Primary Stage In Crushing

What are suitable primary jaw crusher and secondary jaw ...

As a result of infrastructure fast development in "One Belt, One Road", stone jaw crusher and cone crusher have brilliant prospect in African countries. Mr. Santos is one of our customers, who invests quarry crushing plant in South Africa, he has...

Primary biliary cholangitis

Jun 22, 2021 · Primary biliary cholangitis, previously called primary biliary cirrhosis, is a chronic disease in which the bile ducts in your liver are slowly destroyed. Bile is a fluid made in your liver. It aids with digestion and helps you absorb certain vitamins.

USA

The secondary crusher 20 also has two crushing stages. While the primary crusher has been shown merely by wary of example as comprising a twinchambered jaw crusher that provides first and second stage crushing devices, the secondary crusher can, for example, comprise a triple roll crusher having coarse first and fine second stage crushing ...

Jaw Crushers | Heavy Duty | Finlay

J1175. The ® Finlay J1175 tracked jaw crusher is a high performance and aggressive mobile crusher. The machine incorporates a heavy duty variable speed VGF and integrated prescreen to give optimum performance in quarrying, mining, demolition and recycling appliions.

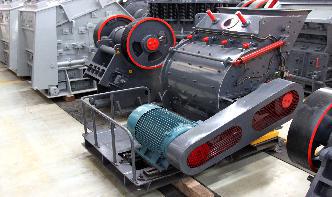

Intensive Mining And Crushing Industry Crusher Machine ...

Jun 28, 2021 · The primary crushing stage is the most economical segment of the aggregate plant in which to make material reduction, after the initial quarry blast. Primary crushing involves reducing shot rock from 40inch minus to 9inch minus rock. The secondary and tertiary crushers reduce the stone from 9inch minus to less than 2inch rock size.

Primary Stages (PrimaryStages) | Twitter

We would like to show you a description here but the site won't allow us.

primary secondary and tertiary crushing

Crushing is usually a dry process and carried out on ROM ore in succession of two or three stages, namely, by (1) primary, (2) secondary, and (3) tertiary crushers. Primary Crusher. Primary crushers are heavyduty rugged machines used to crush ROM ore of (−) m size.

Grizzly bars and feeders improve primary crushing efficiency

Primary Crushing. The primary jaw crusher is the first stage of processing in most sand, gravel, and mining operations. Material that has been excavated from the ground (Pit run) or blasted (Shot Rock) is fed to a large crusher, typically a jaw crusher, where it is crushed down to .

How sugar is made

The primary sugar, glucose, is a product of photosynthesis and occurs in all green plants. ... methods may be used. The pressing process involves crushing the stalks between the heavy and grooved metal rollers to separate the fiber (bagasse) from the juice that contains the sugar. 5 As the cane is crushed, hot water (or a combination of hot ...

Portable Stone Crusher Machine for Sale, Mobile Jaw ...

Crushing is the primary and integral stage in mining operation. Crushing plant is important for mining industry. With the mining technology development, high advanced stone crushing plant are developed, especially portable stone crusher machine, which is gradually replacing traditional stationary crushing .

AMIT 135: Lesson 5 Crushing – Mining Mill Operator Training

This means that the number of crushing stages can be reduced depending on the feed size accepted by primary grinding stage. Image of a "Classical" 3stage ore crushing prior to rod mill [image: (13551)] Diagram of Typical 12 stage ore crushing prior to AGSAG mill [image: (13552)] Calculation of Reduction Ratio in Crushing

How to Impress Your Crush (with Pictures)

Apr 21, 2021 · Let your crush know how you really feel about her. This is the moment of truth. However, after the time you two have spent getting to know one another and flirting, you might find this stage happens much more smoothly than you would have ever anticipated at the start.

Crushing | McLanahan

Oftentimes, shear crushing is combined with other crushing methods, such as compression, attrition and impact, for mineral size reduction. Shear crushing is ideal for crushing friable material or creating a coarse product at the primary crushing stage.

's new high speed MKIII primary gyratory ups the game ...

Oct 17, 2018 · The new Superior MKIII the company says provides a significant performance leap in gyratory crushing. "Based on 's industry leading crushing technology, the MKIII is the first highspeed primary gyratory crusher to deliver up to 30% higher capacity and 70% lower downtime in a comminution circuit."

USA

A crushing plant having elevator means loed primary and secondary crushers, each comprising first and second stage crushing devices. Input material is fed into a receiving unit is separated thereby into pieces of finish size which are discharged onto a delivery conveyor, and pieces of two different larger sizes. The latter are separately fed to the primary crusher stages, which discharge ...

Cedarapids4248 Primary Jaw Crushing Unit | Crusher Mills ...

LT series Primary crushing plants for quarrying and . jaw crushers and over 1,000 impact crushers worldwide. Full mobility – less . occurs when LT110 is used as the primary unit in a twostage crushing process.

Cocoa Butter, Cocoa Powder Manufacturing Process

Third Stage Manufacturing Cocoa Powder 1. Corse crushing After cocoa liquor squeezes out the cocoa butter, the remaining chunk is called cocoa cake. Because of its large volume, it is first coarsely pulverized into a powder. 2. Fine crushing The second time, fine pulverization is carried out to produce more fine cocoa powder and improve the ...

2020 primary and caucus results: Map and delegates

View 2020 primary election results, interactive maps, poll information and candidate fundraising totals in each state and US territory.

Mineral Processing

May 15, 2014 · Primary crushers Jaw crushers Gyratory crusher PRIMARY CRUSHING Reduction of ore = as mined size ~1m to ~ 100 mm size. The objects of crushing are 1) size reduction 2) production of a minimum amount of fines. Primary crushing is done on dry material. The basic equipments for primary crushing 1) Jaw crushers. 2) Gyratory crushers. 3) Roll ...

primary and secondary crushing

The purpose of the primary stage was mainly to crush the stone into conveyable size and thereby make it possible to further process the rock in a continuous process. The secondary stage is the first part of this process so from here on and downwards the crushing and screening plant should be. Chat Online.

primary n secondary crushers for coal crushing diy mortar ...

Primary Crushing Mineral Processing Metallurgy. Feb 26, 2016 The term "primary crusher," by definition, might embrace any type and size of crushing machine. The term implies that at least two stages of crushing are involved, but in many cases the machine which performs the function of initial crusher is the only crusher in the plant.

Mobile Crushing Plant

The mobile crushing and screening plant consists of a primary crushing plant, secondary crushing and screening plant, and a gluebelt conveyor. All levels of mobile crushing stations can be used as an independent working unit to complete the crushing work they have to undertake separately.

In The First Stage Of Crushing Process

Crushing Crushing is the first mechanical stage in the process of comminution it is generally a dry operation and is usually performed in two or three stages Primary crushing the objective of primary crushing is to reduce the size of the rock extracted from the .

Types of Rock Crushers | Quarry Crushing Equipment | Kemper

1. Primary Crushing. As the first stage in a crushing circuit following extraction from a mine site, (or in the case of recycled asphalt production, delivery to the RAP processing plant via truck transport), primary crushing reduces material to a size and shape that can be handled by the secondary crusher.

Nammuldi Overland Conveyor Stage 2 | Process 26

The second stage of the Cape Crushing interim tonnes project was to install a primary crushing station and overland conveyor circuit parallel with the stage 1 plant. Process 26 was engaged to complete the design, procurement and construction of these works which required a purpose built 2500tph overland conveyor system which integrated with the existing Rio Tinto Iron Ore Nammuldi operations.

Latest Posts

- الموردين الأجانب لمصنع الأسمنت المصغر

- البنتونيت كسارة الفك الشركة المصنعة

- مطرقة الحجر الجيري في الصين

- تستخدم كسارات بضرب عمان

- مصنع لتصنيع الطوب التلقائي

- حجر المعدات كسارة التوالي على الديزل

- المبادئ الأساسية لمطحنة الكرة

- عمل آلة محطم

- تكاليف طحن الذهب النموذجية

- مطحنة المطرقة للبيع ملبورن

- على مصنع معالجة الذهب

- سعر كسارة الحجر مصر

- العمودي مطحنة الأسطوانة في غيانا

- مطحنة الكرة لسحق الأردن

- تقدير تكلفة مصنع الأسمنت

- Manufacturing Process Of Aggregate In Construction

- Wet Processing Bentonite Mill Manufacturer

- Zenith Crushing Site In Kenya

- marble crusher in ernakulam

- Perlite Crushing Machine

- Price Finland Crushers

- Conveyor Feed Into Ball Mill

- ราคาหินบดต่อปี

- Cone Crushers Brands

- Coal Mill Classifier Animation

- Stone Crusher In Argentina Cost Rock Crushing Process

- Process Manufacture Of Iron From Iton Ore

- Price Of Crusher For Quarrying Mine In Tanzania

- Mobile Stone Crusher In Uae

- แกลเลอรีเครื่องบดถ่านหิน