Coal Grinding Plant Process

Mineral Comminution and Separation Systems

wastewater treatment circuit necessary for wet plants. In coal preparation wet processing is in preference to dry processing, wherever water resource is available. 3. Components of Mineral Beneficiation Technology Processing of mineral beneficiation is composed of a series of unit operations as illustrated in Figure 1 by a simple example. Raw ore, or 'runofmine ore', is received by the ...

Biomass and Coal: A Powerful Combination |

· When Minnesota Power began cofiring coal and biomass at its power plants in Duluth and Grand Rapids, Minn., more than 20 years ago, they started out combusting 7525 coal to waste wood ratios. Back then, biomass was plentiful and cheap and it was common to get it for free, says Mike Polzin, renewable fuels coordinator for Minnesota Power. "We started burning wood in Duluth only .

News

EPC Project: Gebr. Pfeiffer delivers Complete Coal Grinding Plant to Egypt. Gebr. Pfeiffer, together with its global and local partners, suppliers and subcontractors, is responsible for the complete scope. read more. . Another MVR mill for the Algerian market. MVR 5000 R4 goes to Bechar. read more. . Pfeiffer Director Process Technology Dr Woywadt receives the Global Slag ...

Fine Grinding of Coal by the Turbomilling Process

were both "plant grind," which is 80 pct minus 75~m size. A portion of the Ala bama coal was dryground through 75 ~m (sample 3A) to produce a simulated plantgrind sample. Another portion was crushed to minus mm (sample 3B) for use in autogenous milling and steel shot grinding tests.

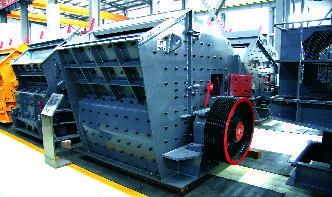

India's coal crushing plant, colliery mining processing ...

Coal is crushed by grinding the coal plant . Coal particles recirculate around four times before reaching the required fineness of handling by the machine . Classifier allows fine particles to escape from the outlet of the mill, while the coarse particles are returned to the mill for further grinding .

Coal Cleaning

The scheme used in physical coal cleaning processes varies among coal cleaning plants but can generally be divided into four basic phases: initial preparation, fine coal processing, coarse coal processing, and final preparation. A process flow diagram for a typical coal cleaning plant is presented in Figure

MS

coal grinding plants In view of the continuous and inexorable increase in the costs of traditional energetic sources, it becomes even more strategic to find alternative solutions that permit the costs for the production of energy to be lowered.

2019 REE Project Portfolio

This Phase 1 project will identify and characterize coalrelated materials, and design and perform a technoeconomic analysis for a selfcontained, modular, and portable continuous ion exchange/continuous ion chromatography (CIX/CIC) pilot plant capable of processing and purifying rare earth elements (REEs).

How Coal Works | Union of Concerned Scientists

· How coal is formed. Coal is formed when dead plant matter submerged in swamp environments is subjected to the geological forces of heat and pressure over hundreds of millions of years. Over time, the plant matter transforms from moist, lowcarbon peat, to coal, an energy and carbondense black or brownishblack sedimentary rock.

STRENGTHENING PLANT SAFETY IN COAL GRINDING MILLS .

It takes as little as kg (3 lbs) of pulverised coal in 28 m3 (1,000 ft3) of air to form an explosive mixture. Since a large boiler burns over 40 kg (88 lbs) or more of coal per second, the safe burning of pulverised coal necessitates strict adherence to planned operating procedures. STRENGTHENING PLANT SAFETY IN COAL GRINDING MILLS AND ...

Coal gasifiion

Coal gasifiion is the process of producing syngas—a mixture consisting primarily of carbon monoxide (CO), hydrogen (H 2), carbon dioxide (CO 2), natural gas (CH 4), and water vapour (H 2 O)—from coal and water, air and/or oxygen.. Historically, coal was gasified to produce coal gas, also known as "town gas".Coal gas is combustible and was used for heating and municipal lighting, before ...

Charcoal machine production line for making all kinds of ...

Briquettes processing plant for shisha charcoal, barbecue charcoal, honeycomb coal. The process of charcoal briquettes plant generally starts with the carbonization of raw materials. Then, the charred coconut shell charcoal and rice husk charcoal will be crushed and stirred (with a certain proportion of binder) to make briquettes.

Coal Preparation

Luttrell, in The Coal Handbook: Towards Cleaner Production: Coal Production, 2013 Abstract: Coal preparation plants incorporate a variety of separation processes that operate in relatively independent parallel circuits. The identifiion of optimum cutpoints for each circuit that globally maximize plant performance have historically involved the use of mathematical simulation routines.

Welcome To Claudius Peters | Claudius Peters

Claudius Peters' role in the world of alumina processing is based upon total ecological awareness coupled with materials handling products that are as competitive as they are reliable. Our expertise in stockyard systems, grinding mills, pneumatic conveying and storage and dispatch systems means we are able to develop systems that benefit our customers and the environment.

A CoalFired Thermoelectric Power Plant

· Georgia Power's Plant Scherer is one of the largest coalfired thermoelectric powerproduction facilities in the United States. It is a 3,520,000kilowatt coalfired facility that provides electricity for Georgia. As this diagram shows, the plant operates on the same principles as other fossilfueled electric generating plants—it burns coal to produce heat that turns water into steam, which ...

Turnkey Project Solutions and Turnkey Plant Solutions ...

Pressure upto: 160 bar, thickness upto: 120 mm. We provide endtoend solutions from project planning, process and product validation, and manufacturing process and engineering, and plant maintenance. In 1962, Chanderpur Group was established by Shri Sumesh Chandra as a oneman company.

Latest Posts

- خطوات المعالجة الكلية

- مكورات خام الحديد تصنيع تدفق الرسم البياني

- 150 صخرة متوسطة 200 200

- كسارة تصادمية لتكسير الفحم في محطات الطاقة

- مصنع جودة الصابورة كسارات الحجر للبيع

- مصنع كسارة الحجر pdf

- تكلفة كسارة نبات كسارة

- شراء آلة concasseur للتعدين الجزائر

- مصنع الذهب وحدات صغيرة

- سرعة العمودية مطحنة

- مبيعات معدات التعدين طحن دائرة كاملة

- ناقل الركام

- مبدأ عمل محركات الهزاز

- خام النيكل طحن مطحنة

- صنع مسحوق الرمال girnee

- Pakistan Crusher Plant Produces

- Powder Roller Mill Manufacturers

- Codes Of Good Practice For The Mining Industry

- Want To Find Industrial Machinery Importer

- Quarry Stone For Sale In Singapore

- New Jersey Compactor Container

- Flc2000 48 30 Flat Hookstrip Shaker Screen

- Conveyor Systems Quarry

- Where To Buy Bulk Artificial Sand In Tamilnadu

- Mobile Iron Ore Jaw Crusher For Sale In Cape Verde

- Equipment In A Gold Leaching Plant

- Burkina Faso Dal Mill Project Subsidy

- gold mining equipment supplier german

- Côte D Ivoire Asphalt Batch Mi Plant Jobs

- Stone Crushing Plant 200 Tph