Limestone Impact Crusher Operating Principle

The Models And Parameters Of Cone Crusher |

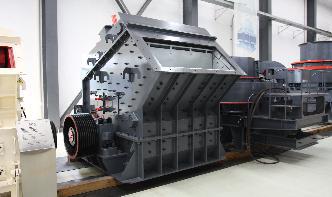

Impact crusher adopts the impact crushing principle, and materials are impacted and crushed between hammer and impact plate. Due to the frequent impact, the wearing parts are easy to damage, so impact crusher has a high requirement on the wearresistance materials. Comparison of applicability The jaw crusher, cone crusher and impact crusher are widely used in a variety of materials, but .

Impact Crusher | Description | Advantages | Types of ...

· But, impact crushers involve an impact method. There is a hopper one side that takes the crushing material into the machine. All material is carried only within a cage. This cage has an opening on the end, bottom and on the side. These openings help in escaping the pulverized material from the impact crusher. Normally such type of crusher is ...

(PDF) SIZE REDUCTION BY CRUSHING METHODS

Operating principle: ... The impact crushers are called as seco ndary impact crushers and are mainl y used in the . second crushing stage. They are suitable for m ediumhard to hard stone and ...

Limestone Impact Crusher Operating Principle

Limestone Impact Crusher Operating Principle. Cme vsi crusher china cme vsi crusher stone crusher spare parts zhengzhou cme crushers mini stone jaw crusher,mine cone crushing plant vsi crusher cme vsi series vertical shaft impact crusher is designed by reputed german expert of, feb 15, 2016 limestone crusher spare parts cme zhengzhou .

The Operation Principle and Function Introduction of ...

The compound crusher is one kind of many crushers. The crusher refers to the machine that can produce final size of above 3mm. According to different working principle and the hardness of materials, there are some commonly used crushers, such as jaw crusher, impact crusher, cone crusher, compound crusher, roller crusher, hammer crusher, mobile crusher etc.

DESIGN AND ANALYSIS OF A HORIZONTAL SHAFT IMPACT CRUSHER

Horizontal shaft Impact crusher 4 Operating principle 4 Design Parameters 5 Chapter 2 Literature Study Performance model for impact crusher 6 Impact energy for crusher 9 Kinematics of hammer rotation 11 Learnings 13 Chapter 3 Design of Basic Components Design of hammer/blow bar 14 Impact bending stress 15 Static load shearing 20 Design of vbelt drive 21 Design Of Anvils 23 Design of rotor ...

limestone impact crusher operating principle

coarse impact crusher operating principlePollo. coarse impact crusher operating principle. FOB Reference Price:Get Latest Price Impact crushers (, hammer mills and impact mills) employsharp blows applied at high speed to freefalling rocks where comminution is by impactratherthan moving parts are "beaters," which transfer some of their kinetic energy to the ore ...

limestone quarry operating principles

operating principle quarry lecafedumarche basic principles in quarry operation. basic principles in quarry operationgreenrevolutionorgin. data from a standard quarry design tool (LSS) and uses this as a basis for a to the restoration of two generic operations a limestone quarry in an upland loion basic principles apply to all quarries to ensure safe and efficient sites during.

Crushing technology | Technologies | Kleemann

Jaw crushers operate according to the principle of pressure crushing. The crushed material is crushed in the wedgeshaped pit between the fixed crusher jaw and the crusher jaw articulated on an eccentric shaft. The material is crushed by the elliptic course of movement and falls down due to gravity. This occurs until the material is smaller than the set crushing gap. The crushing energy acts ...

limestone quarry operating principles

Lime Stone Impact Crusher Operating Principle czeu. Limestone Quarry Operating Principles zionhomes Operation Principle Hammer Crusher For Limestone. Sep 24, 2014Operation Principle stone impact crusher ore crusher jaw stone crushers stone hammer crusher limestone impact Lesson 7 of the Pit Quarry. More

Impact Crusher for Sale with 30800 t/h Processing Capacity

Impact crushing machines are secondary crushing machines, and they are mainly used to crush mediumsized stones. The same thing is that material is squeezed by crushers. While crushing degree is related to crushers' structure and working principle. The crusher is rotating swing. Moving cone is doing eccentric swing while turning to drive the conical liner and fixed liner to squeeze material ...

![Impact Crusher VS Hammer Crusher [7 Pics 10 Tips] | MC](/mkyz976/577.jpg)

![Impact Crusher VS Hammer Crusher [7 Pics 10 Tips] | MC](/mkyz976/210.jpg)

Impact Crusher VS Hammer Crusher [7 Pics 10 Tips] | MC

Hammer crusher is divided into single rotor and double rotor. The main body is composed of box, rotor, hammer head, impact lining plate, sieve plate, etc. it can directly crush the material with the maximum particle size of mm to 25mm or below. 2. Crushing Chamber. The impact crusher has a large crushing chamber, which makes the ...

Impact Crusher Working Principle

· Impact Crusher Working Principle. Starting from the base working principle that compression is the forcing of two surfaces towards one another to crush the material caught between them. Impact crushing can be of two variations: gravity and dynamic. An example of gravity impact would be dropping a rock onto a steel plate (similar to what goes on ...

Impact Crusher | Rock Crusher Machine Manufacturer

Impact Crusher Appliion Field JXSC impact stone crushers are widely used in quarrying, concrete recycling and mining which as a primary, secondary, tertiary crusher. It can crush the materials that pebble, granite, basalt, iron ore, limestone, quartz, diabase, etc. Capacity(t/h): 30500 Max Feed Size(mm): 300700

Impact Crusher

The impact crusher is commonly used for the crushing of limestone, coal, calcium carbide, quartz, dolomite, iron pyrites, gypsum, and chemical raw materials of medium hardness. Effect of process conditions on the production capacity of crushed materials is listed in Table Table Effect of Process Conditions on the Production Capacity of Crushed Materials. Process Condition ...

Impact crusher|Impact breaker|Stone impact crusher|Impact ...

Free training of product operation. Aftersales service. 365 days aftersales online. Solve customer feedback problems timely. Help customers optimize and upgrade equipment. Contact Us ( sales) Working Principle of Impact Crusher. Stone materials fall from the upper end of the stone impact crusher directly into the rotary table. Under the high speed centrifugal action, .

What are the precautions in the use of limestone crusher ...

· What are the precautions for the limestone crusher before starting, during operation and when stopping? The limestone crusher is a heavyduty machine. During the operation, the operator must follow the basic safety matters and operate correctly to avoid accidents! Before starting, running and stopping the jaw crusher, the following three items will be introduced in detail, which will help to ...

Latest Posts

- آلة تصنيع الرمل للبيع

- تدفق عملية وحدة الكسارة

- مصنع سحق التعدين مصر

- مصانع غسيل الكروم فى مصر

- آلات كسارة الصخور على الإيجار

- مصنع معالجة رطبة لخام الحديد والمعادن الأخرى

- مل الكرةل مصنع 100 طن يوميا آلة

- لوازم كسارة الرخام الجميلة

- حجم مختلف من الفحم نحصل عليه بعد الفحص

- مطحنة للبيع سان دييغو

- تكلفة إنشاء محطة الكسارة الكلية

- SBM الصين SBM VSI كسارة

- الشركات المصنعة للماكينات كسارة حجر في مصر

- متعدد الطبقات تهتز الشاشة pdf

- كيف تعمل مطحنة المطرقة الهوائية

- Used Grinding Pulverizing

- Carborundum Valve Grinding Paste Data Sheet

- Are Steel Cord Conveyor Belts Splice Vulcanized

- Sea Crusher 282 Key

- silver ore processing plant

- Stone Crusher Plant 1000t H Cost

- Mobile Crushing Plant

- Hmt Tool And Cutter Grinder Specification

- Rock Crusher Blow Bars

- Limestone Crusher Working Principle In Morocco

- Cardan Shaft For Rolling Mill

- Machines Use For Mika Crusher

- spare parts crusher mills

- Rock Breaker Primary Crusher Plant

- Machinery Details Entry Screen For A Factory