Process Of Iron Ore Screening

iron ore screen testing equipment

Iron ore can be upgraded to a higher iron ore content through beneficiation. This process generates iron ore filter cake which needs to be pelletized to be used in the steel making process. Also during the processing of high grade iron ores which don't need beneficiated fines which are generated can be pelletized and used instead of being

iron processing

iron processing iron processing Ores: Iron ores occur in igneous, metamorphic (transformed), or sedimentary rocks in a variety of geologic environments. Most are sedimentary, but many have been changed by weathering, and so their precise origin is difficult to determine. The most widely distributed ironbearing minerals are oxides, and iron ores consist mainly of hematite (Fe2O3), which is ...

Iron Ore Sinter

Coke breeze (a residue from the screening of heattreated coke [34]) is used in an iron ore agglomeration process, which aggregates fine ore so that it can be used in blast furnaces. Sintering and pelletizing are two common agglomeration processes.

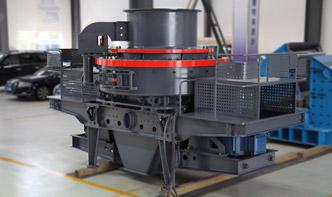

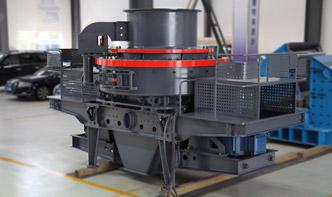

KINGSON CRUSHER Mobile Screen for Mineral Processing (Iron ...

Kingson Crusher Manufacturer of All kings of Stone Crushing Equipment, Accessories and Turnkey Plants including JAW CRUSHER, CONE CRUSHER,,, M...

Hazard Identifiion, Risk Assessment, and Control ...

A roller screening mechanism was used to remove any undersized material before the green balls enter the final stage of production, the induration furnace. ... The various steps of occupational health assessment of hazardous process in an iron ore pelletizing industry are as follows: Process description.

What's the Process of Iron Smelting?

Jan 08, 2021 · Raw materials: iron ore, solvent, fuel Iron ore. It is difficult to meet the requirements of blast furnace smelting in terms of chemical composition, physical state and other aspects of naturally mined ore. It must be prepared and treated by crushing, screening, beneficiation, briquetting and mixing to supply blast furnace with high grade ...

Beneficiation of Iron, Iron Extraction Process, Iron Ore ...

The increasing demand of iron ore at home and abroad further stimulates the development of the benefiion of iron ore. As one of the leading enterprises in domestic mineral processing industry, Xinhai has been dedied commitment to the research and development of iron extraction process and equipment for more than 20 years.

Iron ore

Nov 20, 2020 · Sinter Feed ( mm mm): This is the most usual type of iron ore in the market. It is obtained at later stages of screening. In order to be fed into the blast furnace, the sinter feed must be agglomerated by and transformed into "sinter". The iron content .

of iron ore process in south africa

Iron ore – Anglo American South Africa In South Africa our iron ore operations are made up of a % shareholding in Kumba Iron Ore Limited (Kumba), a leadi

(PDF) Iron ore sintering. Part 1. Theory and practice of ...

1. INTRODUCTION. The sintering process is used to agglomerate a mix. of iron ores (natural or synthetic), return fi nes, fl uxes. and coke, with a particle size of <8 mm, so that the. resulting ...

Iron ore beneficiation process flow for iron ore ...

Iron ore crushing process. Very low grade iron ore in large lumps is firstly sized through crushing process. The common crushing machines used in iron ore beneficiation plant are jaw crusher as primary crusher, cone crusher or fine jaw crusher as secondary crusher. The iron ore materials of required size after screening then pass to the ...

iron processing | Britannica

iron processing, use of a smelting process to turn the ore into a form from which products can be in this article also is a discussion of the mining of iron and of its preparation for smelting. Iron (Fe) is a relatively dense metal with a silvery white appearance and distinctive magnetic properties. It constitutes 5 percent by weight of the Earth's crust, and it is the ...

Mechanical screening

Mechanical screening, often just called screening, is the practice of taking granulated ore material and separating it into multiple grades by particle size.. This practice occurs in a variety of industries such as mining and mineral processing, agriculture, pharmaceutical, food, plastics, and recycling.. A method of separating solid particles according to size alone is called screening.

Iron ore beneficiation technology and process,gravity and ...

Dec 17, 2020 · Iron ore beneficiation technology and process. 121720; 841 Views; icon 0 . Iron ore is one of the important raw materials for the production of pig iron and steel in the iron and steel industry. There are many types of iron ore. According to the magnetic properties of the ore, it is mainly divided into strong magnetism and weak magnetism.

Ore Beneficiation

N. Haque, T. Norgate, in Iron Ore, 2015. Screening and separations. Screening is an important step for dry beneficiation of iron ore. Crushing and screening is typically the first step of iron ore beneficiation processes. In most ores, including iron ore, valuable minerals are usually intergrown with gangue minerals, so the minerals need ...

Latest Posts

- كيف يمكنني شراء آلة طحن الحجر

- تكلفة رأس المال لكسارة الحجر 120 tph في مصر

- سيور ناقلة تستخدم في عمان الفحم نقل

- معدات تعدين الفحم الحديثة

- معدات صانع الرمل

- مطاحن تقطيع الدولميت

- الموردين دولة الإمارات العربية المتحدة جنوب كسارة الفك

- كسارات الحجر للبيع ليبيريا

- مصنعي آلة التكسير اليمن

- الكالسيت طحن الكرة مطاحن

- الميكا المحمول سعر كسارة الصانع

- اندونيسيا شركة سحق

- pe 250 400 كسارة فكية للحجر

- الدولوميت آلات طحن الموردين السعودية

- تكلفة آلة طحن الكسافا في عمان

- Roller Flour Mill Livtar Singh Dahela

- Mineral Ball Mill Manufacturer In Papua New Guinea

- Vibration Feeder Bowl Theory

- Vrrm Mill Sclient=psy Ab

- Moduli Of Fine Sand

- Juxin Brand Pe Series Jaw Stone Crusher

- Milling Machines For Sale

- Mineral Water Plant Fully Layout Diagram Pdf

- Screw Conveyor Discharged

- Jeffrey Rader Hammer Mills For Sale

- Small Portable Mechanical Rock Crusher Gold In Quartz Vein

- Tutorial Surpac 612 Pdf

- Crystal Ore Iron Ore Crusher Spares Nagpur

- Busniss Plan On Agergate Production Sample Pdf

- Price Of Heavy Duty Sbm Iron Ore Crushing Unit