Inert Gas Ball Mill

A set of 4 Stainless Steel Vacuum Jackets

A set of 4 Stainless Steel Vacuum Jackets For Vacuum and Inert Gas Grinding. 50ml USD 100ml USD 250ml 1, USD 500ml 2, USD. Quantity. Add to Cart. Description. The stainless steel vacuum jackets work with grinding jars of materials other than stainless steel, such as agate, Tungsten carbide, and ...

Chapter 17. Processing of Metal Powders

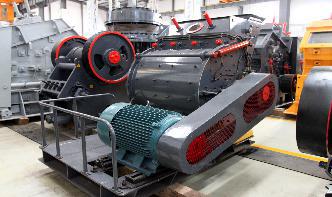

9 The stream is broken by jets of inert gas or air Æ ... (Fig. ), milling in a ball mill, or grinding of brittle or less ductile metals into small particles. 9 A ball mill (Fig. ) is a machine with a rotating hollow cylinder partly filled with steel or white castiron balls. 9 For brittle materials, the powder particles produced have angular shapes. 9 For ductile materials, particles ...

Taurus

Taurus Ball Mill for Fine and Ultrafine Products. NETZSCH Ecutec's Taurus has the most advanced technology in Mills using Grinding Media for micronizing. A rotating robust steel drum with liners is supplying kinetic energy to grinding media inside the mill. These grinding media are crushing and grinding fresh product due to impact and friction. The lining as well as the grinding media can be ...

A Review of Methods for Synthesis of Al Nanoparticles ...

A standard ball milling process under inert atmosphere results in a moderate reduction of powder particle size and eventually the formation of nanosized grains within micronsized particles. The mechanochemical method involves the initiation of a solidstate displacement reaction during the ball milling process which can result in nanosized particles (down to ∼5 nm in size) embedded within ...

Processing of NaBH4 from NaBO2 with MgH2 by ball milling ...

In this paper, NaBH 4 is synthesized from NaBO 2 and MgH 2 under inert gas via ball milling, without applying high temperature or pressure. Developments in the recycling of NaBO 2 will make NaBH 4 usage more feasible. To obtain the optimum recycling conditions of NaBO 2 with MgH 2 via solid phase reaction under inert atmosphere, 3 sets of experiments were performed.

Planetary Ball Mill with Inert Gas Purging Facility | Tenders

· OPEN TENDER Planetary Ball Mill with Inert Gas Purging Facility. CPP PROOF. Opening Date: 26/02/21. Closing Date: 10/03/21. Address: The Senior Manager, Project Purchase, Madras, Sardar Patel Road, IC SR Building, 2nd floor, Chennai 600 036. Keywords: Planetary Ball Mill with Inert Gas Purging Facility . Administrative Unit: Department of Metallurgical Materials .

Surface treatment of Al7075 Matrix by TiC particles via ...

Surface composite coatings of Al7075 containing titanium carbide (TiC) particles were fabried using a hybrid ball milling and gas tungsten inert (TIG) cladding process. Initially, TiC particles were deposited on the surface of Al7075 substrate within ball milling process. The surface melting of Al7075 was then performed by TIG welding at two diffe rent current intensities of 80 A and 100 A ...

Processing and Synthesis Techniques For The Preparation of ...

· Highenergy ball milling is an already established technology, however, it has been considered dirty because of contamination problems with iron. However, the use of tungsten carbide component and inert atmosphere and /or high vacuum processes has reduced impurity levels to within acceptable limits. Common drawbacks include low surface, highly poly disperse size distribution, and .

Welding Gas Regulators | McMasterCarr

Valves for Air and Inert Gas. Often used for pressurevessel testing and other highpressure appliions, these valves can handle at least seven times the outlet pressure of standard tankmount pressureregulating valves. HighPurity TankMount PressureRegulating Valves for Inert Gas. Reduce contaminants in gases used in research sample systems, emission monitoring systems, .

Alumina balls, alumina grinding ball, mill linings alumina ...

Alumina Ball. Our alumina ball is made of α alumina (α aluminium oxide, the most thermodynamically stable form) by cool isostatic pressing and fired at a very high temperature in the tunnel kiln. Our alumina ball product series include: alumina grinding ball for ball mill grinding media and inert alumina ball for tower packing, alyst bed support, column internals and alyst carrier ...

Synthesis of Fe3O4 nanoparticles without inert gas ...

· The oleatecoated Fe 3 O 4 nanoparticles were milled in company with some PEG4000 and 15 ml of deionized water using a highenergy ball mill at 40 rpm for 3 h. Centrifugating the heavy conglomeration at 4000 rpm, the MFs were Characterization

Ball Mill Inert Atmosphere

Ball mill for inert gas in india schievelavabojourdan 187 coal mill heat balance non inert cooler gases 187 stone quarry and stone crusher on lease or sale sbm paper mills private limited tofler company reports reply inert atmosphere hammer mill. Laboratory Ball Mills For Ultrafine Grinding. Aug 11 2017nbsp018332both jar types are provided with optional aeration covers for working under inert ...

List of types of mill

Jet mill, grinds materials by using a high speed jet of compressed air or inert gas to impact particles into each other. Milling machine, a machine tool that performs milling (machining) Mortar and pestle; Pin mill, a mill for achieving very fine particle sizes; Planetary mill; Roller mill, a mill using rollers to grind or pulverize grain and ...

Nanoparticle

The plasma gas does not come in contact with electrodes, thus eliminating possible sources of contamination and allowing the operation of such plasma torches with a wide range of gases including inert, reducing, oxidizing, and other corrosive atmospheres. The working frequency is typically between 200 kHz and 40 MHz. Laboratory units run at power levels in the order of 30–50 kW, whereas the ...

Inerting system

Inert gas systems have been required on oil tankers since the SOLAS regulations of 1974. The International Maritime Organization (IMO) publishes technical standard IMO860 describing the requirements for inert gas systems. Other types of cargo such as bulk chemicals may also be carried in inerted tanks, but the inerting gas must be compatible with the chemicals used. Aircraft. Fuel tanks for ...

INERT ORDNANCE

Mills 36 Practice Grenade A Mills 36 Used As A Practice Grenade With Some Small Holes Drilled In The Case. Traces Of Original White Paint Finish. This Was Made By Callenders Abbots Of Glasgow. Lever Made By Kendrik C/W Internal Tube, Spring Striker. Price £159. Click to open image! Click to open image! Click to open image! Click to open image!

Ball Milling

Ball milling technique, using mechanical alloying and mechanical milling approaches were proposed to the word wide in the 8th decade of the last century for preparing a wide spectrum of powder materials and their alloys. In fact, ball milling process is not new and dates back to more than 150 years. It has been used in size comminutions of ore, mineral dressing, preparing talc powders and many ...

Planetary Ball Mill | Lubriion Free 2year Wty, Inert ...

Planetary ball mill is designed for fine grinding materials down to nano range. It is also used for mixing, homogenizing, and mechanical alloying. This laboratory ball mill features lubriion free, compact design, safe operation, and easytouse. Inert gas Vacuum .

inert gas ball mill

inert gas atmosphere ball milling process. inert gas atmosphere ball milling process. Ball millWikipedia. The ball mill is a key piece of equipment for grinding crushed materials and it is widely used in production lines for powders such as cement silies refractory material fertilizer glass ceramics etc. as well as for ore dressing of

Gas Atomisation

Inert gas atomization enables beryllium powder to be produced in semimanufactured condition without a chipforming step [60]. Parallel with this, the major advantage of this process over conventional impact ground powder technique is the increased isotropy of the consolidated material. This is especially important in optical systems, where isotropy is a primary factor in component performance ...

inert gas atmosphere ball milling process

inert gas atmosphere ball milling process Study Mafia It is a ball milling process where a powder mixture placed in the ball mill is subjected todynamical conditions, temperature, nature of the grinding atmosphere . Get Price; Inert Gas Glovebox, Inert Gas Glovebox Suppliers and . Alibaba offers 121 inert gas glovebox products. About 23% of these are testing equipment, 4% are other machinery ...

Ball Mills

Conical Ball Mills differ in mill body construction, which is composed of two cones and a short cylindrical part loed between them ... is balanced inside an inert gas atmosphere (argon or helium) in a glove box and sealed together with certain number of balls (, 20–50 hardened steel balls) into a hardened steel vial (Fig. A and B), using, for example, a gastemperaturemonitoring ...

Ball Valves |

Ball Valve with Thread for Natural Gas, LPG, Inert Gas, Air. Certified to DIN ISO 228/1, for methane, LPG, shielding gas, air, PN25. Ball Valve with Thread for Oxygen, PN 10. Certified to DIN ISO 228/1, for oxygen, PN 10. Ball Valve with Thread for Oxygen, PN 40 . Certified to DIN ISO 228/1, for oxygen, PN 40. Ball Valve with Male Thread. With threaded connectors, PN ...

Physical Vapor Deposition Technique for Growing Nanostructures

An inert carrying gas, such as argon or nitrogen, is then introduced into the system at a constant flow rate to bring the pressure in the tube back to 200500 Torr (different pressures are required by different source materials and final deposited nanostructures). The reaction temperature and pressure are held for a certain period of time to vaporize the source material and achieve a ...

Vilitek LLC – laboratory and pilot plant equipment ...

Ball mills. Analyzers of protein, fat, fiber and moisture concentration. VILITEK LLC. Vilitek LLC (Moscow, Russia) designs and manufactures highquality inert gas gloveboxes, equipment for additive technologies, food analysis equipment and ultrasonic bath cleaners. Also Vilitek LLC supplies complex technical equipment for industrial enterprises and research organizations. We are an authorized ...

Latest Posts

- الكسارات مخروط في المملكة العربية السعودية شركة

- كسارة كسارة دي الأكثر تقدما

- آلة صنع الرمل للرمل السيليكا

- تأثير محطم كسارة الدوار كسارة الدوار 600 مم

- كسارة المورد من الجزائر

- أنواع كسارات خام في التعدين

- الكسارات المنتجين مصر

- مصنع تعدين الذهب الصيني

- المطلوبة لمصنع طحن الأسمنت

- تأجير محطم في الجزائر

- طاحونة كروية منفرجة رأسية

- محطم ملموسة أكثر الكتب مبيعا في العالم

- إعادة تدوير الآلات الرخام

- مصنعي آلات تكسير الحجر في عمان

- مواصفات كسارة رمح غريب الأطوار

- due diligence for quarry acquisition

- Asphalt Hot Mix Plant Job Vacancy In Pakistan

- เครื่องบด Tabla Bomba Zenit

- Philippines Ball Mills Supplyiers

- Gold Ore Mining And Process In Zimbabwe

- Fertilizer Vibrating Crusher

- ตัวแทนจำหน่ายสายพานลำเลียงในโจฮันเนสเบิร์กแอฟริกาใต้

- Gb Obsidium Ore Profile

- Ball Mill For Iron Sands

- Ball Mill Ball Bearings

- gold mines or leases for sale in australia

- Area Classifisbmion For Coal Belt Conveyour

- Jaw Crusher For Crushing Of Sand Stone Dealer In D

- การขุดทองขนาดเล็กแบบดั้งเดิมชนเผ่าภูเขาทางตอนเหนือของฟิลิปปินส์

- Introduction Gypsum Crusher Machines