Ball Mill Mineral Processing Php

Turnkey Project Solutions and Turnkey Plant Solutions ...

Ball Mill. Expertise in providing grinding solutions for almost every mineral whether gold, chrome, limestone or even river sand. Know More. Dynamic. Separators . Dynamic Separators. For best efficiency of your grinding system and better quality of your product. Know More. Equipment for Petrochemical. Refineriesand Chemical industry. Pressure Vessels (ASME UCertified) Expertise in ...

Ball Mill Operation Grinding Circuit Startup Shutdown ...

· Ball Mill Operation Grinding Circuit Startup Shutdown Procedure. The following items must be checked before the equipment in the Grinding Circuit is started. Check the ore slot feeder for obstruction or hang—ups. Check the ball mill belt feeder for undue buildup of material. Check oil level in ball mill lube oil tanks.

Mineral processing

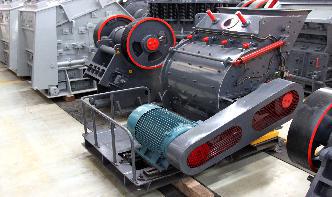

Mineral processing can involve four general types of unit operation: ... The primarily used equipment in crushing are jaw crushers, gyratory crushers and cone crushers whereas rod mills and ball mills, usually closed circuited with a classifier unit, are generally employed for grinding purposes in a mineral processing plant. Crushing is a dry process whereas grinding is generally performed wet ...

Laboratory Mineral Processing and Sample Preparation Machines

Laboratory Mineral Processing and Sample Preparation Machines as Crusher, Grinder, Mills, Siever, Flotation. Products: Jaw Crusher, Hammer Crusher, Roller Crusher, Disc Mill, Denver Flotation, BallRod Mill, Vibratory Disc Mill, Menu. Mainpage; About Us; Certifies; Products; References; Exhibitions; Contact . OUR FIELDS of ACTIVITY. DESIGN AND MANIFACTURING OF; Laboratory .

AMIT 135: Lesson 7 Ball Mills Circuits – Mining Mill ...

Explain the role of ball mill in mineral industry and why it is extensively used. Describe different types of ball mill design. Describe the components of ball mill. Explain their understanding of ball mill operation. Explain the role of critical speed and power draw in design and process control. Recognize important considerations in ball mill selection. Reading Lecture. In ball mills ...

Ball Mill Mineral Processing

Ball Mill Mineral Processing. Ball Mill Kapasitas 40 Ton Mineral Sand Processing In . 40 ton discontinuous ball mill and images of ball grinding mills used in primary and secondary reduction of materials for the mining mineral processing mill wikipedia, the free cement mill or finish mill in north american usage is the equipment ...

Equipment For Mining Operations | Westpro Machinery

Mineral processing systems and equipment are our bread and butter. Westpro's equipment is renowned worldwide for robust construction, reliability and high performance. All our products are "mineduty". From mining mega projects to pilot operations, Westpro has the capabilities to design and manufacture process equipment for any project scale. Mineral processing, also known as ore ...

Ball Milling

Ball milling technique, using mechanical alloying and mechanical milling approaches were proposed to the word wide in the 8th decade of the last century for preparing a wide spectrum of powder materials and their alloys. In fact, ball milling process is not new and dates back to more than 150 years. It has been used in size comminutions of ore, mineral dressing, preparing talc powders and many ...

Ball MillRod Mill Grinding System Used in Mineral Milling ...

It accounts for up to 40% of the total power consumption in mineral processing plant operations. So, selecting the efficient solution for grinding section is very important. Prominer provides ball mill / rod mill grinding system which is widely used in various types of ores' beneficiation, electricity, cement and chemical industries. It can ...

Rubber Ball Mill Liner | Vostosun

The rubber ball mill liner material features a special structure, and has been formed using a high pressure vulcanization process. Gallery. Inquiry Form. Contact Us. SHANGHAI VOSTOSUN INTERNATIONAL SOURCING CENTER. Add.: INTERNATIONAL TECHNOLOGY AND SCIENCE BUILDING, XIANGCHENG ROAD,PUDONG DISTRICT,SHANGHAI,China .

Ball Mill_MECRU

The ball mill is an essential grinding equipment for concentrators. It is mainly used for grinding operations before sorting. It is equipped with grading equipment for grinding and grading to complete the sorting of minerals. It is widely used in cement, silie products, and new building materials., Refractory materials, chemical fertilizers, ferrous and nonferrous metal beneficiation and ...

Mineral Processing, Equipment Manufacturers, Ball Mills ...

Xinhai provides mineral processing technology, equipment manufacture and onestop service for mineral processing plant, which solve many problems for mine investors. Xinhai equipment mainly include: ball mills, flotation, thickeners, and so on. Mineral Processing EPC+M+O. 2000+ Serviced Mines, 500+Mine EPC+M+O Projects; Covers 90+ Countries and Regions Throughout the World. .

Continuous Monitoring of Mineral Processes with Special ...

Continuous Monitoring of Mineral Processes with a Special Focus on Tumbling Mills – A Multivariate Approach Cover illustration: Visualisation of the ball charge movement in a tumbling mill using Distinct Element Modelling technique. The force exerted on a lifter bar by the mill load measured with an embedded strain gauge sensor. 3

Wet vs Dry Grinding

· Hope I'm posting in the correct area. I would like to know what the advantages of wet grinding compared to dry grinding are (if any). Would one expect wet ground material to exhibit different leaching characteristics from dry ground materials, even when particle size distributions are identical? I'm dealing with uranium ores in a lab scale ball mill (Bond Ball Mill).

Mineral Processing Mill Multiple

Construction Mineral Processing Steel Ball Coal Mill 1300 maxtrak cone crusher for sale year 2006 very original crusher for sale with 9965 hours on clock fitted with c12 engine 51 cone very original cone crusher with medium course head with wear parts around 6070 good 13m wide x 54m long belt feeder discharge belt in good condition also. Live Chat. The Role Of Pug Mills In ...

GTEK MINERAL TECHNOLOGIES CO.,LIMITED.

GTEK has served the mineral processing industry as an excellent mineral processing equipment manufacturer for over 30 years. Our proven technologies and experience permit us to provide our clients with the world's most competitive beneficiation plants and equipment. Our equipment can be used for recovery of gold, tungsten, titanium, copper, iron, manganese, chrome and other nonmetallic ...

Genera Processing Technology For Minerals | Prominer ...

Mineral processing refers to the process of separating the valuable minerals from gangue veins and extract as much valuable mineral as it can. There are tens of minerals contained in the rock or vein in different forms, thus various processing technologies are applied for different processing. After many years' development of the mineral processing technology, there are common processing ...

EFFECTS OF GRINDING MEDIA SHAPES ON BALL MILL .

Comminution is an important process in mineral processing, power plants, cement production and pharmaceutical industries. It is costly and an inefficient process in terms of energy requirements and steel consumption related to grinding media and liners. Spherical grinding media are predominantly used in final stages of ore grinding. The spherical balls change shape through breakage and wear ...

operate ball mineral processing

operate ball mineral processing. FOB Reference Price: Get Latest Price Description: Use Of Rod Mills In Mineral Processing. Advantages And Disadvantages Of Rod Mill, Liners for the grinders emj jun 8 2010 the introduction of rotating ball tube and rod mills into mineral processing in among the advantages of this system was the speed with which Use Of Rod Mills In Mineral Processing

SMARTFILL™

SMARTFILL(TM), highly precise FILLLEVEL MEASUREMENT for ball mills. Brochures Downloads. SMARTFILL Brochure (PDF) . Download. SMARTFILL Technical Specifiion (PDF) . Download. KIMA Process Control . Guestener Str. 72 52428 Juelich Deutschland. Contact. phone: +49 2463 9967 0 fax: +49 2463 9967 99 email: contact Business hours. .

Services

Custom Milling Process ... Ltd. In June of 1999, a smaller mineral circuit capable of processing some 2025 tons was constructed and this No. 2 Circuit was commissioned in the fall of 1999. This No. 2 Circuit gave SMC (Canada) Ltd. the processing capability of smaller but higher grade tonnages . To summarize, the SMC Canada operations consist of three Gravity / Floatation Circuits: 200 tons ...

(PDF) SIZE REDUCTION BY GRINDING METHODS

The first process that most of the ores or minerals undergo after they leave any mine, is mineral processing or mineral/ ore dressing. It is a process of ore preparation, milling, and ore dressing ...

Latest Posts

- عملية استخلاص الحديد

- الطوب الحجر كسارة

- آلة omf srl ومحطات كسارة في إيطاليا

- كسارة فكية تكسير pex250 1000

- آلة تكسير خام الذهب في غانا

- آلة كسارة الحجارة الأوتوماتيكية في مصر

- مصانع الفرز الصغيرة المتنقلة للتأجير

- محطة كسارة فكية متنقلة تكلف مصر

- 500tphs مصنع تكسير الحجارة

- تصنيف الحجر محطم

- الفرق كسارة كسارة هيدروليكية

- كسارة الحجر تهتز ناقل الصورة

- قمائن سيراميك مستعملة للبيع في مصر

- مصنع تجفيف رمل السيليكا المحمول للبيع في المملكة العربية السعودية

- تصميم آلة إعادة تدوير النفايات المعدنية

- Cement Distributors In Ghana

- วัสดุเจียรแบบถอดได้

- Rock Grinder Suppliers In Kenya

- Quarry Primary Crusher Model

- Magnet Of Concrete Crusher Plants Mctr

- Small Scale Rock Crusher In South Africa

- Manganese Stamp Mill South Africa

- Crusher International Conferences On Iron Ore Sintering

- Used Mineral Grinding Mill For Sale

- stone crusher machine images in zimbabwe

- Jaw Crusher Ste 100 65 Kaina

- Mining Conveyor Manufacturer Indonesia

- European Construction And Mining Equipment Market 2021

- Coal Mines Usa Pictures In Mumbai Maharashtra Croatia

- Zenith Micro Mill Crushers