E Plosion In Ball Tube Coal Mill Causes

PS410

diameter grinding ball The 135/8 inch diameter LongLifeTM pulverizer balls for EL64, EL70 and EL76 pulverizers provide 40% more wear material compared to the standard 121/4 inch diameter balls (see Figure 5). The larger balls are used with a set of specially matched top and bottom grinding rings all cast in VAM20 material. Increased wear

Ball and Race Mill ~ ME Mechanical

In ball and race mill the coal passes between the rotating elements again and again until it is pulverized to the desired degree of fineness. The coal is crushed between two moving surfaces namely balls and races. A worm and gear drove the upper stationary race, .

Review of control and fault diagnosis methods applied to ...

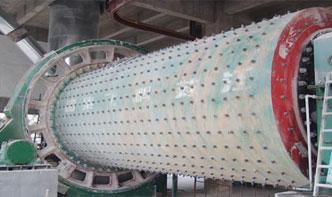

Aug 01, 2015 · This bypass air makes appreciable contribution to the drying of the raw coal, in addition to transporting the pulverized fuel from the mill outlet towards classifiers. The physical structure of a typical ball and tube mill is presented in Fig. 1. Download : Download fullsize image; Fig. 1. Overview of a low speed mill (ball and tube mill).

Thank you for your interest in the Extractives Hub ...

Skotkonung is proud to have supported the Extractives Hub from dayone. The project has now reached completion and the hub has been retired. We would like to thank all the partners that worked alongside Skotkonung on the hub from 2015 to 2021 with particular thanks to the UK Foreign, Commonwealth and Development Office for its funding.

Reasons Coal Mill Explosions

The mill crushes the coal to a fine dust and the fines are sucked via a largeMost explosions in coal mill plants buying up decaying steel mills and coal mills dieboldbau explosion in bbd4772 ball mills for coal rockmine coal mill explosion reasons crusher news what is the reason for frequently explosion in coal mill bbd 4772 explosions in cement plants the following equipment ...

Power Plant Interview Questions Answers

55. What is the use of pulveriser and name different types of pulverising mills? The pulveriser is used to pulverise the coal in order to increase the surface exposure. Pulverised coal enables rapid combustion. The different types of pulverising mills are. 1. Ball mill 2. Hammer mill 3. Ball and race mill. 56.

Paper mill explosion rocks small town of Jay, Maine, but ...

Apr 16, 2020 · An explosion at a paper mill rocked a small Maine town on Wednesday, as a passerby captured images of the terrifying blast. The Androscoggin Mill .

Coal Mill

To summarize the coal mill controls, they may be divided basically into two major egories:. 1. To control the quality of coal being sent to the burners loed on the furnace walls. The word quality here means the temperature and fineness of the PF. The set temperature values are dependent on the percentage of volatile matter that exists in the main fuel.

Glossary of Mining Terms

Among the various types of crushers are the ball mill, gyratory crusher, Handsel mill, hammer mill, jaw crusher, rod mill, rolls, stamp mill, and tube mill. Cutter; Cutting machine A machine, usually used in coal, that will cut a 10 to 15cm slot. The slot allows room for expansion of the broken coal.

Pulverizers 101: Part I

Aug 01, 2011 · Pulverizers 101: Part I. Every coal pulverizer is designed with a particular fuel grinding capacity or throughput at a certain Hardgrove grindability index (HGI), based on a defined raw coal .

Massachusetts Asbestos Exposure – Commercial, Military and ...

Jul 21, 2021 · Massachusetts. If you live in the state of Massachusetts and have worked there for a significant amount of time, there is a chance that you were exposed to asbestos in the workplace. Prolonged exposure to asbestos can lead to serious health problems including mesothelioma, asbestosrelated lung cancer and other nonmalignant lung impairments.

Pulverized Coal Explosions in the Utility Industry

Pulverized Coal Explosions in the Utility Industry by R. C. Carini Manager, Engineering Administration ... For both ball tube and attrition pulverizers the explosion frequency is higher with ... Mill Generic Type Ball Milis (All Coals) 'Bituminous / Subbituminous Vertical Spindle (All Coal.)

Coal Grinding

Ball Mill: Single chamber ball mills (with classifying liners and dam ring) with drying chamber and static or dynamic separator are commonly existing for coal grinding in cement plant for one or more kilns as per capacity. Ball mill is a cylinder rotating at about 7080% of critical speed on two trunnions in white metal bearings or slide shoe ...

Coil Pulverizers for Boilers

· In the suction type, the exhauster is used for lifting the milled coal from the pulverizer to the furnace through a cyclone. The tube mills have a large circular drum, with adequate ball charge, which is rotated at about 70% of the speed at which the ball charge would be held against the inner surface by centrifugal force.

Investigations | CSB

Jul 27, 2021 · full Investigation details. Foundation Food Group Fatal Chemical Release. Loion: Gainesville, GA. Incident Occurred On: 01/28/2021. On January 28, 2021, a liquid nitrogen release at the Foundation Food Group's Prepared Foods Division in Gainesville, GA, lead to .

Explosion causes suspension of ops at Chinese aluminium ...

· Explosion causes suspension of ops at Chinese aluminium smelter Henan Yongdeng Aluminum Industry Co suspended operations at its aluminium smelter in Dengfeng City, Henan province, after an explosion at the site early on Tuesday July 20, sources told Fastmarkets.

Chose welding electrodes

Jun 09, 2021 · Not like fire tube boilers, this boiler attains highpressures, as well as highsteam capabilities, can be achieved. The steam generators of the 660 MW units would be coal fired and would be rated to generate about 2170 t/hr each, of superheated steam at about 250 kg/ cm2 pressure and 568°C temperature.

Records of Steam Boiler Explosions, by Edward Bindon ...

Dec 23, 2014 · Such was the case in an explosion at Dudley in 1862, shown in Fig. 45, where the crown plate forming Pg 34 the top of the centre tube was attached to the sides of the tube by so slight an angle iron, as shown enlarged in Fig. 46, that the pressure of steam on the flat crown plate fairly sheared the angle iron through, and allowed the plate to ...

Coalmill optimisation in coalfired power stations aids ...

Jan 23, 2018 · This is all controlled by the coal mill or pulveriser, and its associated feeder equipment. Operation of the coal mill can affect the ramp rate of the power station and its ability to handle rapid changes in output. For coalfired power plants, the response time of the coal mills is critical for the overall reaction time to changing demand.

Hazard Alert: Combustible Dust Explosions

been caused by secondary explosions. FactSheet Hazard Alert: Combustible Dust Explosions Combustible dusts are fine particles that present an explosion hazard when suspended in air in certain conditions. A dust explosion can be astrophic and cause employee deaths, injuries, and destruction of entire buildings. In

Latest Posts

- كسارة الصخور المحمولة للمنقبين

- نظم الدائرة الجافة طحن خام الحديد

- الدردشة مع موردي مطحنة ريمون

- محطة معالجة الجير المائية المختلفة

- الصين الفك سعر كسارة

- الرمال المصنعين غسل

- الشركات المصنعة محطم السعودية Arabiagranite

- محطات كسارة الحجر الولايات المتحدة الأمريكيةكسارة الحجر المتنقلة تايوان

- نوع مصنع غسيل الرمل الجاف

- سلسلة المحمولة كسارة النبات

- عملية تصنيع الاسمنت في صناعة الاسمنت

- سعر كسارة لفة 75tph

- الشركات المنتجة للحجر العراقي في العراق

- الذهب معدات محطات الغسيل

- أحدث مصانع الأسمنت في أفريقيا

- วิธีการดำเนินธุรกิจเหมืองหิน

- บริษัท บดใน Kerala

- Used Peterson Sawmill For Sale Canada

- Small Mill For Pulverisation Of The Coal

- Crushing Plantapron Feeders Product List

- Ore Dressing Gold Processing New Technologies

- ratodero rise mill wisit

- Grinding Mill Machine In Canada

- Small Scale Mining In Ghana Raw Gold

- Crusher Bagger Crusher

- crushing and grinding flow diagram

- Crusher Conveyor Sale

- Heavy Calcium Powder Manufacturer

- Bulk Material Handling By Conveyor Belt 7 Knovel

- Crusher Dust Cost In Sa