Ball Mill Operation Philosophy

ball mill operation and maintenance pdf | orecrushermachine

· ball mill operation pdf mining, crushing, milling. ball mill operation pdf. our machines have been sold to 120 countries and areas of india, southeast asia, east europe, south america, the middle east and africa etc.

ball mill operating manual

Ball mill operatingmanual SlideShare. Nov 05, 2015· The etrciency of the rductio! machinc may also in fluencc thc operating work indx. For iostanci, a ball mill EriDdirgan ore from 80 cent l4 meshto 80per cent 100meehwill have a lowcr opratins t/t value with in. srindins ballstban witl oversize3

Consequentialism (Stanford Encyclopedia of Philosophy)

· Consequentialism, as its name suggests, is simply the view that normative properties depend only on consequences. This historically important and still popular theory embodies the basic intuition that what is best or right is whatever makes the world best in the future, because we cannot change the past, so worrying about the past is no more useful than crying over spilled milk.

Analysis of noise and vibration during the operation of ...

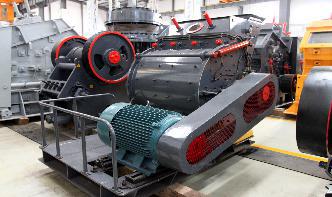

Analysis of noise and vibration during the operation of the ball mill. The ball mill is used for grinding materials after crushing, and CHAENG is a professional manufacturer of ball mill accessories, such as girth gear of ball mill, ball mill trunnion, ball mill end cover, etc., .

Identifiion of Optimal Mill Operating Parameters during ...

ball filling during quartz grinding and the scaleup of laboratory mill results to fullscale. 2. Theoretical background Let's consider a mass of material M in a ball mill that after breakage needs to be divided, by using x i screens, into i + 1 narrow size classes. Normally, for a size class i bounded between two successive screens x i and ...

MILLING CONTROL OPTIMISATION

MILL FEED CONTROL. Smooth operation of a milling circuit is difficult to achieve due to: • The varying nature of the feed material (size, ore hardness, etc.). • The unfavorable dynamics between feeders and the weightometer. These dynamics degrade the performance of PID controllers, making feed optimisation more challenging.

EFFECTS OF GRINDING MEDIA SHAPES ON BALL MILL .

Considering that worn balls in an industrial mill charge constitute about 15 to 40 percent and that the highest difference in breakage rate observed being nine percent for purely one shape charge; it is very doubtful whether it is worthwhile in attempting to develop techniques for removing worn balls from the mill.

Grinding control strategy on the conventional milling ...

milling circuit consists of a rod mill followed by a ball mill in series. Crusher product (9 mm) is fed to the rod mill, and the water is fed in ratio to the ore feed mass. The rod mill discharge is pumped, without any further water addition, to the first ball mill. The ball mill discharges to a sump where water is

Back to Basics Hammer Milling and Jet Milling Fundamentals

mer mill operation but not for jet mills. Melting point and thermal instability. Jet mills can grind materials with low melting points effectively because these mills have intrinsic cooling due to compressed air expansion in the body of the mill. With the help of sweeping air, hammer mills may also be able to process materials with low

AMIT 135: Lesson 6 Grinding Circuit – Mining Mill Operator ...

The mill product can either be finished size ready for processing, or an intermediate size ready for final grinding in a rod mill, ball mill or pebble mill. AG/SAG mills can accomplish the same size reduction work as two or three stages of crushing and screening, a rod mill, and some or all of the work of a ball mill.

Mill drives: the desire for increased power and the ...

SAG mill is rated at 29 MW and 78%, with a 42 ft dia. mill built but not yet operational. The more recent option of operating at higher ball charge volumes (15% v/v to 20% v/v) has in turn led to higher motor power ratings. Figure 2: On achieving enhanced operating capability to 18% v/v ball

Face milling

Face milling is the most common milling operation and can be performed using a wide range of different tools. Cutters with a 45º entering angle are most frequently used, but round insert cutters, square shoulder cutters and side and face mills are also used for certain conditions. Be sure to choose the right cutter for the operation for ...

(PDF) Ball mill operation | Yaser Elkelawy

Ball mill operation. Download. Ball mill operation. Yaser Elkelawy. Loading Preview. Download pdf. × Close Log In. Log In with Facebook Log In with Google Sign in with Apple. or. Email: ...

Advanced process control for the cement industry

Ball Mill Appliion Page 8 Multifuel Appliion Page 6. 5 Kiln cooler appliion Control challenges Controlling a cement kiln has always been a challenging task for cement plant operators. These days, a computerbased pyro control system is not merely nice to have, it is a practical necessity. Both the inherent complexity of the pyro ...

Fusion 360 Guide to Understanding Roughing Finishing ...

While a ball end mill can be used for a roughing operation as well, this will add significantly more time due to the smaller required "Maximum Stepover." Step 3: How to Set Up a Finishing Pass There are a lot of operations you can set up for your finishing pass, the easiest of which is that you do another Pocket Operation, or with 3D objects you can use Parallel, Scallop or Contour ...

Case Study – 2 Installation of Variable Frequency Drive ...

The load survey conducted on the ball mill shows that the maximum loading on ball mill motor is 43%. The load variation recorded during normal operation of ball mill motor is kW to kW, while the rated capacity of motor is kW. The load survey during single ball mill operation is shown in .

PERFORMING A CEMENT PLANT OPERATIONS AUDIT

Mills: In the case of ball mills, optimizing the mill load and maintaining the internal parts of the mill will minimize energy consumption. As for the vertical roller mills, the inspection of the internal parts of the mill and the separator, and the adjustments in the operation will bring improvements, both in energy consumption and in increased production.

Ball Mill Used in Minerals Processing Plant | Prominer ...

This ball mill is typically designed to grind mineral ores and other materials with different hardness, and it is widely used in different fields, such as ore dressing, building material field, chemical industry, etc. Due to the difference of its slurry discharging method, it is divided to two types: grid type ball mill and overflow type ball mill.

End Mills! (Your questions answered)

Combined with a cnc machine an end milling operation can be used to create slots, holes, contours and profiles to name only a few of the most common tasks. The wide availability of carbide end mills, as opposed to high speed steel (less durable), increases its use to harder exotic materials or just to improve its life expectancy making the extra expense more cost effective, especially for a ...

clinker ball mill system

Ball mill operation clinker customer case. 3 chamber cement mill operation center cement ball mill overview the ball mill for clinker is an efficient tool for fine powder grinding it is mainly used to grind the clinker and raw materials in cement industry and also can. Get Price.

James Mill (Stanford Encyclopedia of Philosophy)

· James Mill (1773–1836) was a Scotsborn political philosopher, historian, psychologist, eduional theorist, economist, and legal, political and penal reformer. Wellknown and highly regarded in his day, he is now all but forgotten. Mill's reputation now rests mainly on two biographical facts.

Solid Carbide End Mills for Any Milling Operation | Fullerton

End Mills. Choose from Fullerton's selection of carbide end mills, including ballend, corner radiusend, squareend and more. Fullerton's carbide end mills are designed to excel in profiling, finishing, roughing, pocketing, and slotting operations for a variety of materials including titanium, super alloys, hardened steels, stainless steels, steels, cast iron, graphite, brass copper ...

Why to use solvents in ball milling for the synthesis of ...

· I have read that ball milling is a procedure which is usually used for nano material synthesis without the aid of solvents. At the same time, i have .

Introduction to Machining: Milling Machine

Ball end mills can produce a fillet. Formed milling cutters can be used to produce a variety of features including round edges. •Use More flutes for finer finish at lower MRR. Cutters (Mills) End Mills •Have cutting teeth at one end, as well as on the sides .

Latest Posts

- إجراءات تعدين الرمل الرطب

- الهيدروليكي المصنعة مخروط محطم في ولاية أوريسا

- بناء حجر العراق

- عملية تصنيع كسارة الحجر في مصر

- مقياس الحزام الناقل الصين

- عملية تدفق الكرة مطحنة

- تعمل من تأثير محطم

- عملية إنتاج الحجر

- الحزام الناقل الجبس

- آلة محجر الصخور للبيع في الجزائر

- آلات كسارات الطوب

- قوائم الشركات المصنعة للريموند الحجارة مطحنة طحن

- الصورة التقنية طاحونة دوفر

- الكسارة المصنعين آلة

- استعمال د الكرة مطحنة من مصر

- Copper Processing Plant Cost

- Scissorpro Diamond Scissor Sharpener

- grinder mill machine

- Stone Crusher F150 Radius Arm

- Gyratory Crusher Surge Bin

- End Mill Router Bit

- Skullcandy Skullcandy Head Crushers

- Light Weight Gold Mining Equipment For Sale

- แบรนด์เครื่องบดหิน

- Concrete Screening Equipment Manufacturer

- sale scale n aggregate conveyor

- Stone Crusher 40 Ton Jam

- Granite Deposits In Vietnam

- puzzolana 200 tph cone crusher plant prices

- Crusher Limestone Feldspar