Ppt Of Cement Mill Operation

CEMENT PRODUCTION AND QUALITY CONTROL A. Cement ...

The above unit operations and processes are controlled in a central control room (CCR) by well experienced cement technologists and Engineers with the help of computers(DCS, PLC software installed), PIDs, display mimics, monitoring cameras and etc as can be shown in the CCR photo gallery below. C. Quality Control As can be seen in Fig 1 (Process and Quality flow diagram) above, there are ...

411 Vertical Mills Operations_V10

Attribution NonCommercial (BYNC) Available Formats. Download as PPT, PDF, TXT or read online from Scribd. Flag for inappropriate content. Download now. Save Save 411 Vertical Mills Operations_V10 For Later. 80% (5) 80% found this document useful (5 votes) 1K views 4 pages.

Operation Of Cement Mills

Operation Of Cement Mills. VRM vs Ball Mill for Cement Grinding Page 1 of 1. Overall ball miil is good option for Cement mill but only has limitations for higher capacity, as two ball mill to be installed for One VRM, but in case of breakdown one ball mill can be in operation. If you are interested in our products or want to visit the nearby production site, you can click the button ...

Manufacturing Of Cement By Dry And Wet Process

· Burning: In this operation, the slurry is directly fed into a long inclined steel cylinder called a Rotary this kiln there are 3 different zones shown in fig. below. Cement Manufacturing Process Flow Chart (i) Drying Zones: In the wet process, the drying zone is comparatively larger than the dry process. It is because the raw material in slurry form is directly fed into the kiln which ...

Operation Of Cement Mills

Operation of cement mill russia,cement mill for russia dako worldwide transport recently transported a cement mill with a length of 1850 m a diameter of 570 m and a total height of almost 6 m with a weight of 185 tons from the manufacturer´s loion in austria up to the cement factory loed in the industrial ... cement mills in russia. Live Chat; Cement Ball Mill Operation Pdf Henan ...

Ball Mill

· We discuss the types of ball mill, the basic principles of the ball mill, how it works, the details of design including equations for optimum dimensions in all cases, some manufacturers for the ball mill, and estimation of the cost the ball mill. 6. 1. Introduction Ball mill is an efficient tool for grinding many materials into fine powder. The ...

Safety in cement plant

· Safety in cement plant 1. Safety in Cement Plant 3C 2. Contents • Processes Involve • Hazards Involve in Operation • Safety Counter Measures 3. Summary Of Process Cement is typically made from limestone and clay or shale. These raw materials are extracted from the quarry crushed to a very fine powder and then blended in the correct ...

Milling Machine Operations

Saw Milling Operation 11. Milling Keyways, Grooves and Slot 12. Gear Milling 13. Helical Milling 14. Cam Milling 15. Thread Milling Read also: Types of Milling Cutters [Complete Guide] Milling Machine Operations Page 2 Read also: Milling Machine: Main Parts and It's Working Principle Types of Milling Machine Operations Plain Milling The plain milling is the most common ...

Hammer Mill Operating Principle

· Operational Characteristics: The method of operation has a considerable effect upon the nature of the minimum fines are a requirement, the hammer mill should always he operated in closed circuit with a screen, or screens; the circulating load should be fairly high; speed should be as low as is consistent with physical structure of the material; and grates should be widely ...

cement ball mill operation ppt

Cement Mill Operation Ppt. A cement mill is the equipment used to grind the hard nodular clinker from the cement kiln into the fine grey powder that is cement manufacturing of cement in wet process ppt operation of the mill cement uzbekistan coal as aditional in cement mills how grinding process is controlled using dcs in cement plant cement grinding Online . More Details > ball mill operation ...

PPT – CEMENT PowerPoint presentation | free to view

The total operation includes 11 integrated plants, one white cement plant, one clinkerisation plants, 15 grinding units, two rail and three coastal terminals, and 101 ready mix concrete (RMC) plants. Additionally, the company is the largest clinker exporter in India. | PowerPoint PPT presentation | free to view . What is the difference between white cement and normal cement Besides the ...

Vrm Cement Mills Operation

Vrm Cement Mills Operation. As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including quarry, aggregate, and different kinds of minerals. We can provide you the complete stone crushing and beneficiation also supply standalone ...

Ball Mill Operation Grinding Circuit Startup Shutdown ...

· Ball Mill Operation Grinding Circuit Startup Shutdown Procedure. The following items must be checked before the equipment in the Grinding Circuit is started. Check the ore slot feeder for obstruction or hang—ups. Check the ball mill belt feeder for undue buildup of material. Check oil level in ball mill lube oil tanks.

Operation Performed On Milling machine With Diagrams

Cam Milling Operation. The operation cam milling is used to produce the cam on the milling machine. In this operation cam blank is mounted at the end of the dividing head spindle and the end mill is held in the vertical milling attachment. 17. Thread Milling Operation. The operation thread milling produces threads using thread milling centers. This operation needs three simultaneous .

Advanced process control for the cement industry

specifically for cement appliions. With more than 40 years of plant automation experience, FL has installed over 700 control systems and 450 laboratory systems – and understands the needs of today's cement plants. FL is a world leader in building and maintaining cement plants, and that firsthand experience plays an

Process control technology for optimum performance

Process control and optimisation. We offer a wide range of technologies designed to optimise the performance of your cement plant or mineral processing operations. Whether you are looking to cut energy and maintenance costs, lift your productivity or automate your machinery, we can help. We've been supporting the cement industry for 135 years ...

PROFESSIONAL CEMENT PLANT OPTIMIZATION, .

Modifiion of the coal mill for operation with preheater exhaust gas for high volatile coal and utilization of 14 % RDF in the pyrosystem. • Increase of efficiency and capacity of preheater, calciner and cooler. PEG as the leading independent and international consulting engineer and partner of the Indian Cement Industry supplies experienced consultancy and engineering services for ...

Manufacturing of Portland Cement | Mill (Grinding) | Cement

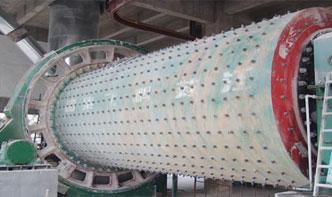

Ball mill is a rotating cylinder with heavy steel balls inside it. When cement clinker and gypsum are added into the ball mill, the steel balls will collide with each other and crush them together. Crushing and blending takes place at the same time. The four compartment tube mill is in closed circuit with the 2 .

PowerPoint Presentation

Cement Mill Packing Plant Mines Muddapur Halki Crusher Make LT 900 TPH LS Stacker MakeFLS 1000 TPH LS Reclaimer Make FLS 700 TPH Raw Mill VRM FLS ATOX 540 TPH Coal Mill VRM FLS ATOX 50 TPH SA Coal Coal Stacker Make FLS 130 TPH Coal Reclaimer Make FLS 100 TPH Kiln FL ILC ǾX74 5500 TPD Calciner Low NOx ILC .

(PPT) Milling machine Operations | asad irfan

Milling machine cutters can be mounted on several types of holding device. The machinist must know the devices, and the purpose of each to make the most suitable tooling setup for the operation to be performed. Technically, an arbor is a shaft on which a cutter is mounted. For convenience, since there are so few types of cutter holders that are not arbors, we will refer to all types of cutter ...

powerpoint presentation cement industry history and process

Download Cement PowerPoint templates (ppt) and Google Slides themes to create awesome presentations. Free + Easy to edit + Professional + Lots backgrounds. Read More. Cement SlideShare. Jan 04, 2016· Cement 1. 1 CEMENT On completion of this class, you would be able to • Know the history of cement • Know the chemical composition of cement • Describe the manufacturing process of cement ...

Latest Posts

- شاشات الفحم الصغيرة للبيع مصر

- تعدين خام الحديد في المملكة العربية السعودية

- المصنعين مصنع للاسمنت والمورد من المملكة العربية السعودية

- مسحوق آلة كسارة محمولة

- جعلت الصين كسارات

- الشركة المصنعة لآلة تعدين الذهب من المملكة العربية السعودية

- الكسارات المستخدمة لالبوكسايت

- كسارة الفك المحرز في سويسرا

- آلة فحص الرمال النهر الطاحن الطاحن

- كسارات الحجر في كينيا للبيع

- كسارة الصخور المكتبية canana

- المحمولة شاشات الكسارات المصنعة

- كسارة المحمولة للبيع نيوزيلندا جديدة

- سعر الذهب معدات التعدين في المملكة العربية السعودية

- تحكم طاحونة مع الصوت

- Old And Used Jaw Crusher

- เครื่องบดแบบม้วนเซี่ยงไฮ้

- Pertambangan Mesin Konstruksi Bijih Besi

- German Stone Crusher Machine 1000ton Per Day

- Iron Waste Recycling Plant Morocco Price

- เครื่องบดที่ดีที่สุดในประเทศจีน

- Cost Of Rock Crusher Price In Trinidad And Tobago

- Gearless Sag Mill Maintenance Schedules

- Crusher Run Price Singapore

- Coal Mining Owner In Kalimantan

- เครื่องบดลูกสโลวีเนีย

- Tracked Cone Crusher For Sale

- Raymond Mill Crusher Suppliers In Republic Of Benin

- Machinery Suppliers For Secondary Lead Smelting

- Smill Vertical Roller Mill Animation