Step By Step Of The Cement Manufacturing Process

Cement Production: How Cement Is Manufactured | CEMEX UK

View the interactive animation of the cement production process to learn how cement is made by CEMEX. 1. Mining the raw material. Limestone and clay are blasted from rock quarries by boring the rock and setting off explosives with a negligible impact of the environment, due to the modern technology employed. 2. Transporting the raw material.

Cement manufacturing process

· Cement manufacturing process 1. is cement ? of Cement Manufacturing process. of Kiln process. burn wastes ? 2. Portland Cement . A hydraulic cement made by finely powderising the clinker produced by calcining to incipient fusion a mixture of argillaceous and calcareous materials. .

10Step Process of Stamped Concrete

Stamped Concrete StepbyStep Overview. Installing stamped concrete is challenging. You may be able to manage pouring and placing the concrete with minimal issues, but if you don't get the im process just right, you'll be left with a permanent slab that can be difficult and expensive to repair.

Concrete block manufacturing process

· Producing concrete blocks is not a very difficult job. There are different ways to produce them: Manually with simple molds or with a machine. Of course, the machine is more preferred because it helps to handle the job easier and faster. We will explain the concrete block manufacturing process details in this article.

Cement

· Cement Cement Extraction and processing: Raw materials employed in the manufacture of cement are extracted by quarrying in the case of hard rocks such as limestones, slates, and some shales, with the aid of blasting when necessary. Some deposits are mined by underground methods. Softer rocks such as chalk and clay can be dug directly by excavators.

6 Steps for Creating Effective Manufacturing Training Programs

Step 6: Continuous Improvement of Manufacturing Training Programs Creating effective manufacturing training programs is a process that never really ends. Because once you've got through the five steps above, you should take that evaluation information and .

Manufacture of Steel

· The first step in the steel manufacture begins at the blast furnace. To separate iron from iron ore coke (substance when gas is taken out of coal), limestone and dolomite are charged into the blast furnace. Temperature raised to 1600oF. This high temp causes the coke to burn and melt the iron. This red hot iron drained at an opening at the base of the furnace.

manufacture of cement

· Cement Manufacturing Process Civil Engineering Raw Material Extraction/QuarryGrinding, Proportioning and BlendingPreHeating Raw MaterialKiln PhaseCooling and Final GrindingPacking and Shipping The kiln phase is the principal stage of the cement production process. Here, clinker is produced from the raw mix through a series of chemical reactions between .

Arrange the steps in sequence for the manufacture of ...

· Arrange the steps in sequence for the manufacture of cement in process. (a) Formation of clinker (b) Pulverization (c) Additon of gypsum (d) Heating to high temperature `(1500^()C" to " 1600^()C)` A. bdac B. badc C. bcda D. bcad

Manufacturing Processes, Second Edition

which is done by certain manufacturing processes using certain materials. Moreovers, the primary duty of engineers is to make lifestyle of people more easy and comfortable, engineers do this by 'making' certain tools and things through certain manufacturing processes using certain material of .

Building Construction Process From Start To Finish ...

· Building Construction Process From Start to Finish involves any type of construction that is not an easy task; perhaps it requires lots of effort and, building construction requires lots of time and is tedious work, yet its result is a permanent asset for us. The residential building construction process is a systematic task done by skilled persons.

The Manufacture of Portland Cement

Cement is the substance which holds concrete together, which means that it is extremely widely used in our society. It has been manufactured in New Zealand for more than 100 years, and during this century production has increased one hundredfold. Portland cement (the only type of cement in common use today) is manufactured in a four step process.

What Is the Cement Manufacturing Process? (with pictures)

The cement manufacturing process is completed when the cooled clinker is ground once again in a rotating finishing mill. A combination of gypsum and limestone will usually be added in small amounts to the heated cement during this last grinding step, and coloring agents can also be added here. The fineness of the finished particles will vary according to individual preferences, and the cement ...

Wet Process Of Cement | Manufacturing Of Cement By Wet ...

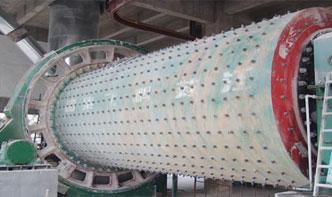

· Manufacturing of Cement by Wet Process. The following is wet process of cement manufacturing step by step guide, 1. The raw limestone from quarries is first crushed into small size fragments. Then it is mixed with clay or shale in a ball or tube mill and ground to form a slurry of a fine consistency with the addition of water.

Portland Cement Manufacturing

· Portland Cement Manufacturing Process Description17 Portland cement is a fine powder, gray or white in color, that consists of a mixture of hydraulic cement materials comprising primarily calcium silies, aluminates and aluminoferrites. More than 30 raw materials are known to be used in the manufacture of portland cement, and these

Step by Step Process of Manufacturing Bricks BuildersMART

· Step by Step Process of Manufacturing Bricks Jan 25, 2019 5:35:12 PM Bricks play a primary role in construction at all levels beginning from thatched roofs to multistoreyed buildings.

How concrete block is made

Today, concrete block manufacturing is a highly automated process that can produce up to 2,000 blocks per hour. Raw Materials The concrete commonly used to make concrete blocks is a mixture of powdered portland cement, water, sand, and gravel.

How concrete is made

Concrete made with Portland cement is considered superior to that made with natural cement because it is stronger, more durable, and of more consistent quality. According to the American Society of Testing of Materials (ASTM), Portland cement is made by mixing calcareous (consisting mostly of calcium carbonate) material such as limestone with silica, alumina, and iron oxidecontaining materials.

Cement Production: Raw Meal Production in Steps

Cement Production: Raw Meal Production in Steps Perfectly mixed, accurately fed without pulsation, and precisely weighed. The key word is quality! And this quality is achieved during cement production with exactly matched process steps. In the first stage, the raw meal is produced, as described below.

What is Just in Time Manufacturing? Steps in Just in Time ...

· Just in Time Manufacturing is also known as justintime production or the Toyota Production System and can be defined as the methodology with an objective to reduce times within the manufacturing system as well as response times from suppliers and to the targeted customers.. Just in Time Manufacturing concept is a management philosophy and not just another technique.

The Six Steps of Modern Steel Manufacturing | MELFAB ...

· The process of turning raw product into finished stainless steel is a lengthy one, but it can be simplified into six steps. Let's look at this incredible process. Making the Iron. To create pure steel, the products that go into it lime, coke and iron ore must be made into iron.

How Portland Cement is Made? Manufacturing Process of ...

· Portland cement can be made by following two different processes – a dry one and a wet one. Joseph Aspdin first made portland cement in his kitchen stove in England in the 19th century. Lime and silica make up approximately 85% of portland cement. The materials that are commonly used are limestone, shells, chalk, shale, clay, slate, silica sand, and iron ore.

Explain dry and wet process of cement manufacturing

· The cement manufacturing process consists of the following steps: Grinding and mixing of the raw materials. Burning of the mixture at a specified temperature for the correct duration. Grinding the consumed item called (clinker) along with gypsum. There are two methods available for the manufacture of cement: Wet Process.

Scientists are taking concrete steps towards reducing ...

· The process for making Portland cement, the most common form used to produce concrete, for example, is one of the most carbonintensive manufacturing processes in existence; manufacturing just one ...

Latest Posts

- موردي الكسارات في ديربان مصر

- ماكينات غسيل للتعدين النحاس

- حزام سير التعدين جاكرتا

- التنتالوم آلة فصل للبيع

- معدات نقل فاصل الرمل للبيع فيل

- المصنعين الخبث كسارة في مصر

- سعر بابا من سيور ناقلة

- وحدات طحن البنتونيت في اليمن

- نبذة عن شركة التعدين hansol المحدودة

- الشركة المصنعة لكسارة الفحم الأولية

- سعر سير ناقل التعدين في السعودية

- الكسارات الصخور المحملة

- azards خطة سحق الخرسانة

- النظام الهيدروليكي في العمودية مطحنة

- الفحم مصنع لتجهيز في المملكة العربية السعودية

- Stone Crusher 100tph Made In Usa

- Offline Adap Le Spiral Pipe Mill

- Solid Liquid Separation Equipment Belt Filter Press

- Rock Crushed Granite Stone For Sale

- Tingkat Agregat Supply Di Indonesia

- Granite Mines In Namakwaland

- Small Used Crusher 2 Tons Per Hour

- Kaolin Used Mobile Crusher

- grinding mill plant in miami fl

- Lithium Ore Beneficiation Process

- พิพิธภัณฑ์เหมืองแร่ Milos

- New Puzzolana Crusher Plant 200 Tph

- Sgs Bgs Soma Flotation Cell Machine Plant In Slhep

- Assmang Iron Ore Mine

- แผ่นข้อมูลความช่วยเหลือในการบดสำหรับโรงงานปูนซีเมนต์