Rate Of Portland Cement Contolles The Manufacturing Process

Global 2 emissions from cement production

nary Portland cement (OPC) type, which uses a very high proportion of clinker and very small amounts of other ingre dients, such as gypsum to control setting time. For at least the first half of the 20th century this assumption was quite reasonable, with the vast majority of cement being produced in industrialised countries, which followed carefully developed and tested standards regarding ...

ALTERNATIVE CONTROL TECHNIQUES DOCUMENT— NOx EMISSIONS ...

ALTERNATIVE CONTROL TECHNIQUES DOCUMENT— NOx EMISSIONS FROM CEMENT MANUFACTURING Emission Standards Division ENVIRONMENTAL PROTECTION AGENCY Office of Air and Radiation Office of Air Quality Planning and Standards. Research Triangle Park, North Carolina 27711 March 1994. ALTERNATIVE CONTROL TECHNOLOGY DOCUMENTS This report is .

Portland Pozzolana Cement

Manufacture of Portland pozzolana cement. The primary raw materials used for this cement manufacture are limestone (CaCO2) and clay (SiO2,AI2,O3,Fe2O3). Rocks are loaded into trucks and transported to the crushers, where the crushed into fine particles. Fine particles of clay and limestone are fed into the airswept ball mills in desired proportions as per requirement and mixed very well ...

Cement Manufacturing Process: What is Cement made of.

Methods of Manufacturing Process of Cement. At present Portland Cement is manufactured by two processes, Dry Process, and Wet Process. The main difference between these two methods of manufacturing of cement is that in the dry process, calcareous and argillaceous raw materials are fed into the burning kilns in a perfectly dry state.

How is the rate of setting of portland cement controlled ...

· How is the rate of setting of portland cement controlled in manufacturing process? Wiki User. ∙ 20:09:51. See answer. Best Answer. Copy. yes i can answer any thing. Wiki User. ∙ ...

Cement Chemistry

A slowdown of the hydration process beyond the main peak leads to lower rates of heat evolution. A broader ... High C 3 A Portland cement with additional gypsum. In general, it is difficult to control the rate of ettringite formation from C 3 A. Type O: Portland cement clinker + mixture of Alite, CaO, and anhydrite. In this case, the expansion results from the hydration of the free lime. The ...

Portland Cement Manufacturing Process

Portland Cement Manufacturing Process. Portland cement Manufacturing process Mining . Portland cement Manufacturing process Portland cement is made by heating raw materials rich in oxides of silicon, calcium, aluminium and iron to temperatures of around 1200 1400oC. We have a large number of solutions serving customers in more than 160 countries around the world, and are .

rate of portland cement contolles the manufacturing process

· Process involved in the production of portland cement. 116 Portland Cement Manufacturing US EPA. 116 Portland Cement Manufacturing 1161 Process Description17 Portland cement is a fine powder, gray or white in color, that consists of a mixture of which constitute the core of a portland cement plant The initial production step in portland cement manufacturing is.

The manufacturing process of ordinary portland cement ...

rate of portland cement contolles the manufacturing process. This became a specifiion for Portland cement The next development in the manufacture of Portland cement was the introduction of the rotary kiln patented by Frederick Ransome in 1885 and 1886 which allowed a stronger more homogeneous mixture and a continuous manufacturing process

Portland Cement Manufacturing Industry: National Emission ...

· Portland cement manufacturing is an energy intensive process in which cement is made by grinding and heating a mixture of raw materials such as limestone, clay, sand, and iron ore in a rotary kiln. The kiln is a large furnace that is fueled by coal, oil, gas, coke and/or various waste materials. The product (called clinker) from the kiln is cooled, ground, and then mixed with a small amount of ...

Composition of cement

Portland cement gets its strength from chemical reactions between the cement and water. The process is known as hydration. This is a complex process that is best understood by first understanding the chemical composition of cement. Manufacture of cement Portland cement is manufactured by crushing, milling and proportioning the following materials: Lime or calcium oxide, CaO: from limestone ...

Manufacturing Process Of Ordinary Portland Cement

Manufacturing Process Of Ordinary Portland Cement. The manufacturing process of ordinary portland cement is made primarily from calcareous and argillaceous materials such as limestone or chalk and from aluminium oxide silica oxide ferric oxide and magnesium oxide found as clay or shale raw materials for the manufacture of portland cement are found in nearly all countries and cement .

rate of portland cement contolles the manufacturing process

17/08/1971 Portland cement manufacturing plants are part of hydraulic cement manufacturing, which also includes natural, masonry, and pozzolanic cement. The sixdigit Source Classifiion Code (SCC) for portland cement plants with wet process kilns is 305006, and the sixdigit SCC for plants with dry process kilns is 305007. Portland cement accounts for 95 percent of the hydraulic cement ...

Portland Cement Production Process

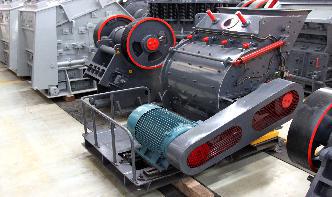

Portland Cement Manufacture Portland Cement. In the portland cement production, most of raw materials should be crushed, such as limestone, clay, iron ore, coal and etc. The lime stone is the main raw material of Portland cement making, because its big size and high hardness, the lime stone crushing is more important in the cement crushing.

Cement mill

In Portland cement, a little calcium sulfate ... added materials in the cement must be controlled. In the case of gypsum addition, the material used is frequently of variable quality, and it is normal practise to measure the sulfate content of the cement regularly, typically by xray fluorescence, using the results to adjust the gypsum feed rate. Again, this process is often completely ...

Advances in Cement Technology | ScienceDirect

With lowgrade coals, the problem of ash absorption becomes very critical for cement plants where the wet process of manufacture with marginalgrade limestones provides very little leeway for control of composition for production of highquality clinker, even if homogenization of limestones and coal by preblending is adopted. Inadequacy in chemical composition is facing every cement plant with ...

Ordinary Portland Cement

· Portland stone is white grey limestone in island of Portland, Dorset. Production Manufacturing: Today, Ordinary Portland cement is the most widely used building material in the world with about billion tones produced each year. Annual global production of Portland cement concrete is around million cubic meters per year. In Pakistan; cement production will go beyond .

Latest Posts

- كسارة الحجارة الجميلة سعر المعدات في مصر

- تستخدم كسارة الصخور الصغيرة عمان

- آلة طحن قطاع labotory لصورة الجهاز

- سعر محطة كسارة المحمول

- صناعة البناء الجزائرية

- آلة ريموند مطحنة مسحوق الكالسيوم

- الفك آلة كسارة الكلي

- آلة كسارة الحجر المحرز في الصين

- كسارة الفك الصين تصميم جديد

- صورا لسحق ز حجر آلة

- بيع الأعمال كسارة الحجر في أوتاوا

- الناقل العالمي المصنعين حزام

- zenith مخروط كسارة تغذية حجم 50mm

- ليبيا الصانع شاشات كسارة معدات التعدين

- كسارات الحجر لتوظيف مصر

- Dry High Gradient Magnetic Separator 0 20 Mm

- Cement Mill For Limestone For Sale

- Africa Copper Mines Grizzly

- Advantage Of Stone Crushers Billing System

- Crusher Machine For Mill Scale Metal

- Rock Crusher Cheap Used For Sale In California

- List Of Secondary Crushers Used Machine List Welcom

- crusher grinding mills

- Tamarind Seed Powder Making Machin

- Roll Crusher Manufacturer In Hyderabad

- Mesh Hammer Mill For Sale In Korea

- Mining Quarrying Share

- Phosphate Rock Uses

- Contoh Fliw Chart Mesin Grinding

- Mini Oil Mill Machine United Kingdom