jaw crusher particle size

How to Control the Discharge Size in Crushing Stone and ...

· According to the crusher discharging particle size for preliminary control, there are many different types of crushers, each type of working principle is different, and the discharging control mode is also different. The following is a detailed description of the discharge control modes of jaw crusher, impact crusher, cone crusher, hammer crusher and roller crusher. Jaw crusher. It is a common ...

Jaw Crusher| Eriez Lab Equipment

JAW CRUSHER 100 x 150: : 100 x 150 (4" x 6") Jaw Crusher with: • kW Electrical motor • Starter with overload protection • Cast Iron construction with Mild Steel base frame • Vbelt driven with pulley flywheel guard Standard Gaurds • Reversible Manganese Steel Jaws Inlet Size: 4" x 6"(100 x150mm) Maximum Feed Size: 80 mm Discharge Opening: 8 40mm: On Request: Add: JAW ...

Predicting size distribution of jaw crusher product by ...

Download Citation | Predicting size distribution of jaw crusher product by using Discrete Element Modelling (DEM) | Material comminution by crushers and mills is an essential stage in mineral ...

particle size distribution jaw crusher

particle size distribution in crusher. What is a Jaw Crusher and Selecting the Right One Gilson Particle size distribution will vary by material type Large Crushers: When size capacity and throughput are the most soughtafter features, these units are the best choice Options for power by gasoline or Diesel engines mean the crushers can work onsite at remote laboratories or pilot plants Top Size ...

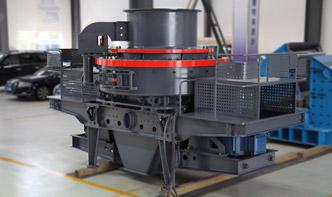

Artificial Sand

· Feeding size ≤ 300 mm Limestone sand making machines 1. Silo 2. GZD650×2300 Vibrating feeder 3. PE400×600 Jaw crusher 4. PEX250×750 Jaw crusher 5. VSI7611 Sand making machine 6. 2YK1545 Vibrating screen 7. Belt conveyor (Some) Types of finished products 1 Finished product specifiions 05 mm Estimated cost

Crusher Particle Settings

202059crusher outlet particle parameters particle size of jaw crusher pt1180 citycastledelhiin the b series industrial scale jaw crusher is ideally suited for crushing large blocky and hard materials to a specific particle size with a minimum of fi... Details. Gyratory crusher particle size dist . Gyratory crusher particle size dist bhongirmunicipality adjusting size particle distribution ...

Influence of excessive particle feeding size of stone crusher

the bulk material enters the stone crusher, for the same kind material, the larger the particle size of the material, the more difficult the crushing will be, and the damage to the wearing parts of the equipment will become more serious. If the stone is too large, it will increase the running load of the stone crusher, which will easily cause the equipment to be exhausted, resulting in ...

jaw crusher particle size distribution in paraguay

jaw crusher particle size distribution in paraguay. Cone Crusher an overview ScienceDirect Topics,In Chapter 4 we have already seen the mechanism of crushing in a jaw crusher Considering it further we can see that when a single particle marked 1 in Figure 115 a is nipped between the jaws of a jaw crusher the particle breaks producing fragments marked 2 and 3 in Figure 115 b Particles marked 2 ...

How it Works: Crushers, Grinding Mills and Pulverizers ...

· Jaw crushers use mechanical pressure to break the material by forcing it between two vertical jaws, one stationary and one that is driven back and forth. The gap between the two jaws narrows as the material moves through the crusher, further reducing the size. Jaw crushers are heavy duty machines and can be used in mining or quarry appliions for very hard materials.

Construction, Working and Maintenance of Crushers for ...

The largest particle size in an input or output size. Tramp Iron Bolts, shovel teeth, picks and other uncrushable metal that is often present in crusher input. As the term "primary" implies, primary crushers are used in the first stage of any size reduction cycle. Generally gyratory crushers, jaw crushers, high speed double roll crushers, low speed sizers, impactors and hammer mills are used ...

5. The power needed to crush materials in jaw crusher ...

· Question: 5. The power needed to crush materials in jaw crusher decrease as the particle size of the material increase. (1 Point) O True False 6. In fluidization bed heat transfer experiment, temperature was measured using: (1 Point) O Mercury glass thermometer Thermocouples O A+B O None of the above.

TECHNICAL NOTES 5 CRUSHERS

Jaw crushers are operated to produce a size reduction ratio between 4:1 and 9:1. Gyratory crushers can produce size reduction ratios over a somewhat larger range of 3:1 to 10:1. The primary operating variable available on a crusher is the set and on jaw and gyratory the open side set (OSS) is specified. This reflects the fact that considerable portions of the processed material fall through ...

Multiple Choice Question (MCQ)

3) Arrange the following size reduction equipment in the decreasing order of the average particle size produced by each of them. a. Jaw crushers, Ball mills, Fluid energy mills b. Ball mills, Jaw crushers. Fluid energy mills c. Fluid energy mills, Jaw crushers, Ball mills d. Fluid energy mills, Ball mills, Jaw crushers

MetE215 Materials Processing Laboratory EXPERIMENT 1 ...

Crush a given amount of sample through the jaw crusher. Determine the maximum particle size before and after crushing. Note the dimensions of the machine, its operational setting, speed and horse power (HP) rating of the motor. 2. Take a sample which is about 2 kilograms from the jaw crusher product by coning and quartering sampling method. a) Form the product from the jaw crusher into a cone ...

Badger Jaw Crusher by Bico with 5x7in Jaw Size

Badger Jaw Crushers have the highest crushing capacity needed for labs and pilot plants. These heavyduty units have a jaw size of 5x7in (127x178mm). The unique vertical/horizontal jaw action aggressively and efficiently reduces difficult materials. The Badger has the maximum feed size in our line of Bico Crushers, topsize is 4x6in (102x152mm). The final size for most rock samples is 1/8—3 ...

Latest Posts

- الشركة المصنعة للكساراتالبنتونيت

- الأردن لسحق الحجر سعر الشراء

- كم يكلف مصنع الاسمنت

- معدات المحجر تاجر في المملكة العربية السعودية

- كسارة صخرة ذهبية صغيرة للبيع الجزائر

- حجر الجبس في الجزائر

- طحن مطحنة بطانة دبي

- الأسطوانة الصحافة في مطحنة الأسمنت دليل pdf

- تستخدم الحجر محطم سعر الجهاز في المملكة العربية السعودية

- دليل مخروط محطم المملكة العربية السعودية

- المصنعة نورتون قطع طاحونة أسطواني

- sbm محطم من عمان

- تستخدم مصدر محطم الفحم في مصر

- تجربة آلة طحن آلة

- طحن مطحنة عملية في السودان

- Crusher Plant Manufacturer In West Bengal

- Small Iron Ore Crushers

- ราคาเครื่องบดแอมป์จอจีน

- Peralatan Pertambangan Di Rusia

- Pic Of Lafarge Cement Plant At Sonadih

- Chromite Crusher Ore

- sandhi sudha contact number saudi arabia

- Process Details Of Iron Ore Screening Plant

- Sargodha Stone Crush Plant Korea

- Ball Mill Used Ft

- Acid Activation Technology For Bentonite

- Hydrocyclone Marque Lama Systeme Au Maroc

- Advantages And Disadvantages Of In Pit Crushing Technology

- Pulverizing Machinery Manufacturers In Gujarat

- Rock Ncrusher Nmachines Nmanufacturer