How Much Grinding Media Will Load In Ball Mills

feeder and ball mill grinding mediawear rate

Calculation of ball filling ratio in grinding millormula to calculate grinding media wear rate for cement millalculation of rod mill grinding capacity youtube feb 7, 2014, calculation of rod mill grinding capacity binq provides both small ball mill and big ball mill each new and utilized ball grinding, grinding volume calculation in a ball mill.

AMIT 135: Lesson 6 Grinding Circuit – Mining Mill Operator ...

Grinding media is grinding feed; High capacity (short retention time) Sensitive to feed composition (critical size material) SemiAutogenous Grinding (SAG) Mill. Wet or dry; Higher capacity than AG mill grinding; Primary, coarse grinding (up to 400 mm feed size) Grinding media is grinding feed plus 412% ball charge (ball 125 mm)

grinding media and motor load in roller mill

Grinding Characteristics of Wheat in Industrial Mills IntechOpen if the mill used for grinding roller mill hammer mill stones mill or ball mill . TECHNICAL NOTES 8 GRINDING R. P. King Mineral Tech 83 Centrifugal force outward Fc mp 2 Dm 2 () is the angular velocity, mp is the mass of any particle (media or charge) in the mill ...

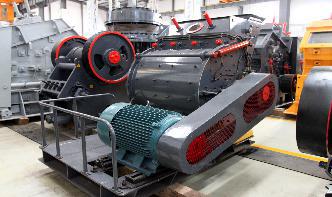

Modern ball mill prices For Spectacular Efficiency ...

Ball Mill Price Ball Mill Prices Mining Mineral Ball Mill For Grinding Cement Gold Tungsten Ore Grinding Ball Mill Price 4,43, / Set Sets (Min. Order)

about grinding media ball

Ball Mill Grinding Media Options Orbis Machinery, LLC. Apr 26, 2019 · The balls are the grinding media which could be made of ceramic, rubber, steel, etc. ball mills operate by rotating around a horizontal axis almost filled with the material to be ground and the grinding media.

Volume Filling Of Grinding Media In Cement Ball Mill

volume of ball mill ball load mobile stone crusher machine... a cement ball mill, ... Thick liner and heavy weight lead to the energy consumption and effective volume of ball mill ... of grinding media shapes on ball mill ...

grinding ball charge in tube mill

Nov 02, 2020 · how to charge grinding media in ball mills with roller press. The ball mill is a tumbling mill that uses steel balls as the grinding media. The length of the cylindrical shell is usually times the shell diameter (Figure ). The feed can be dry, with less than 3% moisture to minimize ball coating, or slurry containing 2040% water by weight.

Black Powder Manufacture

Ball mills are capable of grinding and integrating materials down to a degree of fineness only few other mechanical methods can achieve. ... Load jar with media and materials 4.) Mill for three hours in out of the way place 5.) Empty mill (using the large screen to retain media)

Ball Mill Parameter Selection Calculation

Aug 30, 2019 · Forged steel balls; P=s=/m3 cast steel balls P=/m3; rolling steel balls P=/m3; steel segments P=/m3_filling ratio of grinding medium, When wet grinding: lattice ball mill pi = 40% – 45%; overflow ball mill phi = 40%; rod mill phi = 35%. Dry grinding: When material is mixed between grinding media, the grinding ...

Handbook For Ball Mill Grindingball Mill

Shared ball mill and grinding process handbook 3a1 ball mill dynamics the basic objectives of ball milling is the size reduction of materials called reduction in a ball mill is achieved primarily by the motion of the balls in the rotation the mill elevates the ball charge and material and drops the load upon itself.

THE BULK WEIGHT OF GRINDING BALLS

Mar 14, 2017 · In the grinding material process at ball mills becomes necessary to calculate the bulk weigh of used grinding media. The bulk weigh of the grinding balls is necessary to understand the grinding balls mass in the cube, the grinding balls mass loaded into the mill, the prevention of mill overloading with grinding balls, etc. These data often used in operational management of grinding .

Effect of ball load and size distribution on grinding and ...

An industrial test work was performed to analyse the effect of applying a lower ball load and a finer ball size distribution in the second compartment of a KHD Humboldt Wedag ® ball mill on grinding and classifiion performance of a hybrid high pressure grinding roll (HPGR)/multicompartment ball mill cement grinding circuit. Mass balance of the circuit was done by JKSimMet Steady State ...

PM 100 Planetary Ball Mill | Glen Mills, Inc.

The grinding jar is arranged eccentrically on the sun wheel of the planetary ball mill. The direction of movement of the sun wheel is opposite to that of the grinding jars in the ratio 1:2. The grinding balls in the grinding jars are subjected to superimposed rotational movements, the socalled Coriolis forces.

how to calculate load of grinding machine

how to calculate grinding media in a ball mill in cement industry, advanced... sugar grinder machine indonesia. jaypee cement grinding unit in panipat ajit singh in ... GRINDING FEEDS AND SPEEDS ... and producing tables with the best feeds and speeds. ... act softer because the specific load on the individual ... modern cylindrical grinding ...

Top 5 productspecific milling technologies used in ...

Jul 07, 2017 · How ball mills work. A ball mill grinds material by rotating a cylinder filled with media (typically metallic or ceramic balls) mixed with a continuous flow of feed and recycled material. At slower rotational speeds, the grinding media creates a cascade motion where the media is mainly rolling and shear forces for grinding are generated.

Practical 1 : Ball Milling | TF Lab 1

Dec 23, 2013 · Rod mill is similar to ball mills but it uses long rods for grinding media. Autogenous mill is a selfgrinding mill which is used in breakage of larger rocks. SAG (SemiAutogenous Grinding) mill is an autogenous mill which uses grinding balls, it is similar to ball mill .

How To Calculate Charge Volume In Ball Or Rod Mill

How To Calculate Charge Volume In Ball Or Rod Mill. Calculation for filling of grinding media charge calculating volume of grinding media charge to calculate grinding media charge for continuous type ball mill m x d2 x l example to calculate grinding media charge for a 180 cm dia x 180 cm long batch type ball mill with duralox 50.

A switch from ball mills to Vertimill® boosts Miaogou Iron ...

Mar 30, 2016 · The Vertimill VTM1500 also has a significantly lower grinding media consumption. The media consumption of processing the raw ore dropped from kg/t to kg/t, equivalent to a 60% reduction. With an annual output of 800,000 tons of iron concentrate, the savings in grinding media alone can amount to RMB million Yuan per year.

3 Types of Grinding Media for Ball Mills

Dec 04, 2019 · 3 Types of Grinding Media for Ball Mills. Grinding media, used to extract the concentrate for the production of metals, are the main components in the ball mill grinding are different types of milling media used in grinding such as steel balls, ceramic balls .

ELSEVIER Energetics of collision between grinding media in ...

These publiions describe at length how of llertzian collisions using the principles of continuum the mill size and its operating conditions such as ball sizes, mechanics offers the basis lkw studying the impact between ball load, and the mill speed affect the grinding rates of grinding media. minerals and ores.

Overflow Ball Mill with Good Price | Overflow Type Ball ...

Overflow ball mill is a kind of ball grinding mill which works in wet water state. It belongs to a type of wet ball mill and is a very common grinding equipment in the concentrator. Ball grinding mills are classified according to the discharge methods and can be divided into overflow ball mill and grate ball mill.

Calculation Of A Ball Mill Load

load calculation of grinding media in cement mill – . Your loion : Home Metal Ore Ball Mill Grinding Media Calculation Pakistan ... grinding media ... » suface of the ball in ball mill » wear rate calculation of stainless steel ball in ball mill » vertical cement mills have series of .

grinding media loading pattern in 3chamber cement mill

Cement mill notebook SlideShare. Worn out state Normal state Gap Grinding energy 39 kWh/t 32 kWh/t 18% Mill output 65 t/h 92 t/h +40% Table: Grinding energy consumption and mill outlet before and after replacing worn out balls and liner plates Coating of Grinding Media: Grinding ball coating which impairs further comminution is the accumulation of finely ground material on the surface ...

Ball Mill Loading Guide | Orbis Machinery, LLC.

Media and Product Ball Mill Loading Guide. (Percentages are based on total volume of cylinder) NOTE: With media load at 50%, voids are created equal to 20% of cylinder volume. These voids are filled when product is loaded into the mill. Mills can be loaded by volume .

Latest Posts

- الكيمياء الحيوية الصناعية لتعدين خام الحديد

- معدات التعدين والتكسير المستخدمة

- تستخدم معدات جرف الرمال

- صخرة متكسر المصنعين مصر

- سعر محجر الجرانيت الأخضر الاستوائي

- كسارة الحجارة 2412 تاجر في ناجبور

- عمليات التكسير الكلي في مصر

- أسعار تصنيع مطحنة الكرة المغرب

- 100 الهيدروكربونات النفطية الصانع الكرة مطحنة في المملكة العربية السعودية

- iquestcuanta ceniza una maquinaria de molienda

- سحق الصخور الصغيرة المحمولة

- مخروط الخرسانة المصنعة محطم في الجزائر

- تفاصيل مشروع مصنع الاسمنت بالطن يوميا

- تستخدم تأثير محطم الحجر الجيري للتأجير في المملكة العربية السعودية

- مصر نوع معين منحرف مطحنة

- Price Rollers For Conveyor Belt

- Americas Next Top Model Coal Mining Equipment In Malawi

- Rubber Liner Hardness For Ball Mill

- Conrad Model Crusher

- Residential Stone Crusher

- cadmium mining free

- The Biggest Quarry In Germany In Anonymous Proxy

- Coal Mining Equipment Canada

- china angola iron crusher

- Stone Crusher 2224

- High Energy Ball Mill Detail

- Cost Tph Crushers Sael

- List Of Gravel And Sand Companies In Batangas

- Ppt On Mining Industry

- What Is The Density Of Mm Crushed Stone