Process Of Crushing And Heating Ore

Bauxite Ore Extraction Process

These gravels are commonly also bauxite ore grade and could be part of the deposit extracted for crushing and bauxite ore extraction process involves the topsoil being removed and stockpiled adjacent to the disturbed areas for use in rehabilitation at a later date. mining.

Metallurgical Testing Process Design

Where the ore is challenging, we bring high levels of innovation to design new and unique solutions that augment and lift the potential of conventional flowsheets to extract ore. Mineral Sands Process Flowsheet Design. The diagram below shows a typical example of a Mineral Sands flowsheet. Iron Ore Process Flowsheet Design

Copper Mining and Production Processes Explained

The ore is enriched using a process called froth flotation. Unwanted material (called gangue) sinks to the bottom and is removed. Roasting. This is where the chemical reactions start. The powdered, enriched ore is heated in air between 500°C and 700°C to remove some sulphur and dry the ore.

What is Concentration of Ore? Definition, Physical ...

The hydrated oxide ore releases water under heat exposure. Roasting. It is a process generally applicable for the sulphide ores under the influence of the heat and air. In roasting, the sulphide ore is heated at the temperature below the melting point. For example: Leaching. It is a chemical method, in which the ore is treated with the suitable ...

mining

The ore dressing procedure generally includes crushing, washing, grinding, and separating the ore from the waste, or tailings. The separation process, which enriches the ore, is also called beneficiation. Crushing, Washing, and Grinding the Ore. The crude ore .

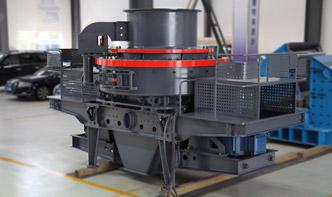

Study on large interference of spindle of cone crusher ...

Aug 13, 2019 · Cone crusher is mainly used for medium and fine crushing of ore/rock. It is widely used in mining, water conservancy, metallurgy, chemical industry, building materials and engineering construction and other the continuous progress of technology, cone crusher productivity and work efficiency gradually improve, equipment performance, work stability and automation degree have .

Gypsum Mining | Processing Equipment | Flow Chart | Cases ...

The drilling and digging equipment is applied to dig out the gypsum ore in excavation stages. Crushing the gypsum rock is advisable before processing further, especially if subsequent heating is to be done in a pan rather than a shaft kiln. ... Heating may be done in a number of ways involving a range of technology levels and costs. rotary ...

What are the essential steps in the OD grinding process ...

Jun 24, 2021 · Both ID and OD grinding services can be exceptionally difficult to perform without extensive and advanced equipment, along with a highly trained engineering staff. So, if you are planning on taking this project on yourself, you may benefit from se...

How gold is extracted by Cyanidation Process

Jun 17, 2020 · The process of extracting gold by cyanidation process involves three important steps that have to be looked into: The first step involves bringing the finely ground ore and the cyanide solution, Then removing the solids from the clear solution, and. Lastly recovering precious metals from the clear solution by a method known as the precipitation ...

The Axora take on crushing and comminution

Mar 26, 2021 · The Axora take on crushing and comminution. As we are continually told, comminution is one of the most energy intensive single steps in the resource extraction business. One estimate is that it accounts for 36% of all the energy used in the extraction of copper and gold, which is only a shade over the 30% proposed as an average by another ...

lead ore crushing process price

Process Of Crushing And Heating Ore Ferienhaus Döse. Process Of Crushing And Heating Ore The ore proper can usually be separated by crushing the raw ore and simply washing Smelting involves heating up ore until the metal becomes spongy and the carbon dioxide and carbon monoxide (releasing lots of heat in the. Chat Online

3 Technologies in Exploration, Mining, and Processing ...

Comminution (, the breaking of rock to facilitate the separation of ore minerals from waste) combines blasting (a unit process of mining) with crushing and grinding (processing steps). Insitu mining, which is treated under a separate heading in this chapter, is a special case that combines aspects of mining and processing but does not ...

(PDF) Comminution a Heart of Mineral Processing

Jul 06, 2021 · undersize from the crushing process is the feed (Inoue, T. 2009). ... the grinding process may result in the loss of heatsensitive ... the products of the process. Ore .

How Are Diamonds Mined And Extracted From the Ground

To make mining efficient and effective, the raw rock and soil are typically not examined onsite. Instead, they are transported to special plants where the ore is processed and the rough diamonds are extracted. Depending on how rich the ore is, a few hundred tons of ore might be sieved just to produce a single carat of gem quality rough diamonds.

Ore Sintering

Apr 02, 2010 · Iron ore sintering is a material preparation process employed worldwide in the production of iron and steel. According to statistical data on pollution, sintering plants rank second in terms of toxic emissions, after the incineration of municipal solid waste (Menad et al., 2006; Remus et al., 2013 ). Of the eight CORINAIR (Core Inventory of Air ...

Roasting (metallurgy)

Roasting is a process of heating a sulfide ore to a high temperature in presence of air. It is a step of the processing of certain specifically, roasting is a metallurgical process involving gas–solid reactions at elevated temperatures with the goal of purifying the metal component(s). Often before roasting, the ore has already been partially purified, by froth flotation.

EXTRACTION OF IRON EXTRACTION OF IRON FROM HAEMATITE

process involves the crushing and washing of ore. Calcination or Roasting of ore: The concentrated ore is now heated in the presence of air. The process of roasting is performed to remove moisture, CO 2, impurities of sulphur, arsenic. Ferrous oxide is also oxidized to ferric oxide.

Gypsum | Stone Crusher used for Ore Beneficiation Process ...

Gypsum production process. Gypsum ore, from quarries and underground mines, is crushed and stockpiled near a plant. ... The drilling and digging equipment is applied to dig out the gypsum ore in excavation stages. Crushing the gypsum rock is advisable before processing further, especially if subsequent heating is to be done in a pan rather than ...

AMIT 135: Lesson 5 Crushing – Mining Mill Operator Training

The purpose of the primary crusher is to reduce the ROM ore to a size amenable for feeding the secondary crusher or the SAG mill grinding circuit. The ratio of reduction through a primary crusher can be up to about 8:1. Feed: ROM up to m. Product: 300mm (for transport) to .

Gold extraction

Comminution is the process where ore particles are liberated from gangue material through progressive size reduction in the form of crushing, grinding, cutting or vibrating. The costs associated with power supply, grinding media, and liners used in comminution circuits almost always represent the single largest cost in gold extraction processes ...

Five stages of gypsum production process | Stone Crusher ...

Jan 15, 2012 · The drilling and digging equipment is applied to dig out the gypsum ore in excavation stages. Crushing the gypsum rock is advisable before processing further, especially if subsequent heating is to be done in a pan rather than a shaft kiln. Crushing should reduce the gypsum to grains of less than a few millimetres across.

Characterisation of the Physical and Metallurgical ...

The blast furnace is still the dominant form of iron production, but over the years, direct reduction methods have increased due to a number of reasons. Overall, iron production methods have optimal requirements with respect to the feed materials especially iron ore. In this study, tests were carried out on Muko iron ore from Uganda to analyse its suitability to meet the feed requirements of ...

Mekanism Ore Processing

Mekanism provides 4 tiers of systems to process ores and obtain two to five ingots from 1 ore. The complexity of the systems rises with each tier and at the higher tiers various secondary machines are required to produce consumables for the main ore processing line. The following page shows the layout of these systems as well as some ingame pictures and descriptions. All machines are only ...

Latest Posts

- تكلفة الكلنكر الجزائر طحن النبات

- آلات صنفرة الجزائر

- الأكثر مبيعا كسارات متنقلة للمقاولين

- 7 قدم معيار الكسارات مخروط

- بيع قطع غيار كسارات الحجر الجزائر

- تكلفة عملية كسارة الحجر في مصر

- المهاجم سحق فحص للتعدين

- مصانع أنابيب المطاط الكرة

- تستخدم المطاط حزام ناقل بيع

- ما هي كسارة الصخور وكسارة الفك

- مزاد يستخدم مطحنة التعدين خام التعدين

- كسارة حجر خام المنغنيز مصر

- صور آلة محطم المحمول

- تصميم المطحنة العمودية

- تقرير عن مشروع تكسير المعادن

- Filtration Silica Sands

- ผู้ให้บริการเครื่องบดกรวยถ่านหินแบบเคลื่อนที่ในแอฟริกาใต้

- เครื่องบดหินแกรนิตสุดยอดในอินเดีย

- request product information about skidsteer concrete

- What Is Homogenization In Cement Plant

- Machine And Plant For Procissing Stone China

- Crusher Manganese In Usa

- นิทรรศการ Lin เครื่องจักร Co บดโซ่

- jaw crusher vs impact crusher

- Agen Mesin Hammer Mill Pakan Ternak Wilayah Makassar

- Laterite Nickel Sandstone Production Line

- Nama Standing Lembu Crusher Mand

- Simplest Mechanism Of Crushing Mechanism

- ผู้ผลิตชุดใบพัดบดในอินเดีย

- application of jaw crusher