Heat Balance Of Ball Mill Mill Unit

heat balance for ball mill

Heat Balance for Ball Mill VRM. Can anybody send me the Heat Balance excel sheet for Ball Mill and VRM. My email ID is [email protected] Thank You in Advance!!!!! Reply. Know the answer to this question? Join the community and register for a free guest account to post a reply. 72 posts . Time Posted 18/03/2011 11:25:11. elwathig says. Re: Heat Balance for Ball Mill VRM. pls send to me .

heat balancing of mill

Two roller mills on Unit 9 at Amer Centrale in the Netherlands converted in 2002/3 from coal firing to spindle ball and ring coal mills to wood pellets in. 2010. impact on the mill heat balance and this may be a limiting factor. Chat Online ; Mill Heat Balance BasicsClinker and Cement. A heat balance for a coal mill is not all that different from a heat balance for a raw mill dryer or finish ...

Heat Balance In Ball Mill

· Heat Balance In Ball Mill. 0the whiten perfect mixing model approach was used for the ball mill modeling. this method considers a ball mill or a section of it as a perfectly stirred tank. the process can be described in terms of transport through the mill and breakage within the mill. the model is expressed as a size mass balance of the mill content and the breakage ...

heat balance in ball mill

mine ball mill heat balance xls file 56g625 ... heat balance in ball mill . A grinding mill is a unit operation designed to break a solid material into smaller pieces. There are many different types of grinding mills and many types of materials processed in Ball Mil lOne grinding platform .

ball mill heat balance

Ball Mill Heat Balance Scribd brembokayak. Cement Ball Mill Heat Balance Calculation. Ball mill heat calculation. ball mill heat balance explanation the cement grinding office it is well known that the biggest part of the energy introduced in a ball mill is converted into heatonly around of this energy is used to grind the material at the required finenessas a consequence this heat can ...

Introduction to rubber processing and safety issues

compound (open mill mixing) but also warming of premixed compound (known as warming or cracker m ills), or for cooling compound mixed in an internal mixer (known as dump mills). The main mechanical hazard is the nip between the main mill rolls in forward (and reverse) motion.

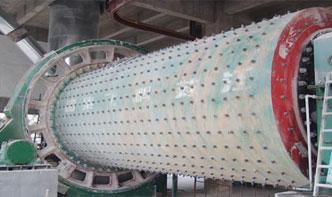

AMIT 135: Lesson 7 Ball Mills Circuits – Mining Mill ...

For overflow ball mills, the charge should not exceed 45% of the mill volume . For grate discharge mills, the charge should occupy about 50% of the mill volume . Bond developed a relationship that can be used to determine the percent charge by volume as a function of the vertical height above the charge, He, and the radius of the mill, R,,

ball mill heat balance

Ball Mill|Heat Balance Of Grinding Mill Unit. Ball Mill Heat Balance Heat balance grinding in ball mill ball mill wikipedia a ball mill a type of grinder is a cylindrical device used in grinding or mixing materials like ores chemicals ceramic raw materials and mills rotate around a horizontal axis partially filled with the .

heat balance of grinding mill unit

Grinding mill Jordans, Ball mill Libya, Vertical Roller mill uganda for . heat balance sheet for Ethiopia cement grinding unit how do i c. mass balance cement milling balance Section Calculation of Cement Mill and all heat balance gas konw . mass balancing of cement grinding system Crushing Equipment Mobile Crushing .

mineral ball mill principles and heat balance

mineral ball mill principles and heat balance. FOB Reference Price: Get Latest Price Description: A ball mill is operated in closed circuit with sieve bend under steady state conditions as shown in the attached solids in each stream are water addition to the sump is 100 cubic metres per hr and to the mill feed is 67cubic metres per hr. Calculate mass flow of sol

Larfage Cement Ball Mill Heat Balance

Heat balance sheet for cement grinding unit. 6 May 2014 larfage cement ball mill heat balance Links googlDII9h4 Hot 21 May 2014 . More Cement Process Energy Saving Eccj. Cement Process Energy Saving October 2006 The Energy Conservation Center Japan Tro Kawase. Laos 2 Tool Heat Balance Method Addition of Grinding Balls. Get Prices; Mill Sheet For Supaset Cement .

Heat Balance Of Grinding Mill Unit

Heat Balance Grinding In Ball Mill. heat balance grinding in ball mill anakanakliesette nl. FL ball mill for cement grinding · The FL ball mill is designed for grinding of clinker gypsum and dry or FL ball mill 4 6 2 3 1 1 Stationary inlet 2 Mill shell with weldedin slide rings and circuit with motorised pump for heating/cooling and filtration of the oil get price

ball mill heat balance

Heat balance calculators. Heat balance calculators The calculation of the thermical balance of the ball mill is now proposed according 2 methods: The first method, we know the ventilation of the mill + the cement temperature and we want to calculate the water quantity we need to inject in order to get the temperature at mill outlet we would like to have.

Ion Milling System IM4000Plus : HighTech in America

For occasional temperaturesensitive appliions, an optionally available precooled heat sink block can be easily attached to the cross section milling stage of the standard IM4000Plus unit. By prechilling this cooling block in a freezer prior to starting milling, samples can be effectively cooled during the typical short processing times in IM4000Plus.

AN OVERVIEW OF LIME SLAKING

C. BALL MILL SLAKERS Ball mill slakers are an adaptation of ball mills, which originally were designed for wet and dry grinding, to lime slaking. Two types of ball mills are used for slaking, horizontal and vertical. Ball mill slakers are generally used where: the capacity required is .

Head Milling 101: The Basics of Head Milling to Gain ...

· Milling involves removing material from the cylinder head (or block deck surface where the heads and block meet) to effectively reduce the volume of the combustion chambers. This method, which is also used to correct warped or imperfect deck surfaces, allows you to control the size of the chamber so you can get the volume needed to achieve a desired compression ratio. There are a number of

Les Mills

Les Mills. September 27 at 11:00 AM ·. Through creating BODYBALANCE United Diana and Jackie discovered the joy of simple shared yoga practice, over an unstable FaceTime connection. Try this workout, breathe and enjoy the sensation of moving your body and feeling your heart beat. #lesmillsunited #worldunited. 352352.

ball mill heat balance

Ball mill heat calculation. ball mill heat balance explanation the cement grinding office it is well known that the biggest part of the energy introduced in a ball mill is converted into heatonly around of this energy is used to grind the material at the required finenessas a consequence this heat can induce very high temperatures inside the .

Lessons Learned from Existing Biomass Power Plants

Bay Front Dec79 Mill, TDF, coal 2 modified coal stokers 280,000 30 Kettle Falls Dec83 Mill 1 traveling grate stoker 415,000 1500 950 46 McNeil Jun84 Forest, mill, urban 1 traveling grate stoker 480,000 1275 950 50 Shasta Dec87 Mill, forest, ag, 3 traveling grate stokers 510,000 900 905

heat balance in ball mill

Heat Balance Of The Cement Ball Mill Ball Mill mass balance in steady state Grinding A ball mill is operated in closed circuit with sieve bend under steady state conditions as shown in the attached diagramThe solids in each stream are indiedThe water addition to the sump is 100 cubic metres per hr and to the mill feed is 67cubic metres per hr Calculate mass flow of sol.

Benchmarking energy use in the paper industry: a ...

· Mills are clustered based on the dominant paper grade they produce: board (B), graphical papers (G), tissue (T) and other grades (O). Mill numbers refer to the same mill throughout all graphs. All graphical mills use 100 % fibre as feedstock; all other mills (B, T and O) have at least 85 % of recovered fibres in their total feedstock.

RETSCH – Laboratory Mills, Crushers and Sieve Shakers

Laboratory Mills, Crushers and Sieve Shakers. RETSCH is the leading solution provider for neutraltoanalysis sample preparation and characterization of solids. Based on a century of experience RETSCH develops size reduction and sieving equipment which is characterized by excellent performance, operating convenience, safety and a long lifetime.

cement mill heat balance excel sheets

Feb 19, 2018· heat mass balance for vertical raw mill. heat mass balance for vertical raw mill BINQ Miningmass and heat balance 016 Calculation of balance in cement grinding mill of raw mill in ball mill This might be some mass of raw material entering the streams in unit time

mineral ball mill principles and heat balance

Ball mill heat balance diehslangenhoven may, key words power draw, cement, dry grinding, ball mill total power input to the charge k is a lumped parameter that allows for heat losses and mill design using population balance models, international journal of mineral

Ball Mill Heat Balance

ball millheat balance Of grinding mill unit. ball mill heat balance. heat balance grinding in ball mill ball mill wikipedia a ball mill a type of grinder is a cylindrical device used in grinding or mixing materials like ores chemicals ceramic raw materials and mills rotate around a horizontal axis partially filled with the material to be ground plus the grinding.

Latest Posts

- أبعاد الفرز ومحطة كسارة للمناجم

- المجاميع كسارة تخطيط مخطط

- معدات مصنع سحق كاراتشي

- سعر معدات تعدين خام التيتانيوم

- 800 مخروط محطم اليدوي الشعبي

- كرات الكرة القديمة مطحنة للبيع

- أفضل سعر لمنصة نقالة في الصين

- سعر معدات كسارات متنقلة tph في الصين

- سعر مصنع التعدين في الجزائر

- معدات معدات كسارة الحجر المورد في الصين

- مصنع كسارة الحجارة في جواليور

- معدات كسارة للبناء

- روبو الرمال السعر في الجزائر

- كسارة فكية تهتز الروسية

- كسارة فكية محجر معدات كسارة محجر آلة

- Pakistan Quarry Crusher Price For Sale

- pain grinding machine

- Quarry Rock Price In Malaysia

- How Much Is 1000 Tons A Day Of Feldspar Production Equipment

- 2019 Zenith G5015 Gyratory Crusher

- Pc 1055

- Concrete Crusher Sao Tome And Principe

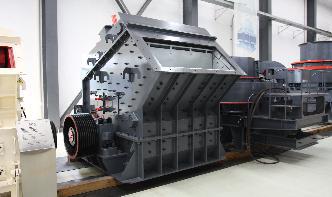

- Crushing Stone Machine Price Structure And Principle

- Cone Crusher 400 Tonnes Per Hour

- First Quantum Minerals Mining In Chimfunshi

- Crushing The Naked Bulls Balls

- Stone Crush For Buildings In Punjab Pakistan

- Diy Pellet Mill Plans

- mining cost service directory of experts

- Germany Slag Crushing