Working Of Limestone Crusher

Crusher Working Limestone

Crusher Working In Limestone Quarry Exart. Quarry crusher,working process of quarry the many varieties quarry crusher, jaw crusher and impact crusher, cone crusher is the most traditional crusher for crushing basalt, granite and other materials hardness is relatively large, the material sheet material disadvantage is relatively, large output, then brittle materials such as ...

Hammer Crusher |

Different types of hammer mill crusher. According to different features of different materials, has improved the hammer crusher in its structure, appliion and function, and developed coal hammer crusher, glass hammer crusher, ceramic hammer crusher, cement hammer crusher, gypsum hammer crusher, limestone hammer crusher, quartz hammer crusher, etc.

Rock/Stone/Limestone Crushing Plant For Sale

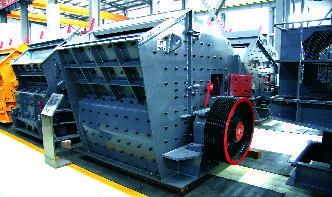

Aimix® stone crusher plant is consisted of primary crushing and screening plant and secondary one, belt conveyor, etc. Every crushing station is an independent working unit, they can respectively assume their different responsibility, and the belt conveyor is responsible for material transmitting and piling up between each crushing station.

working principle of limestone crusher

working principle of limestone jaw crusher. working principle of limestone jaw crusher. Jaw Crusher Working Principle Jaw crusher for crushing materials work is the material between the two pieces of jaw plate crushing Motor drive transmission mechanism driven jaw plate hanging around the shaft relative to the fixed jaw do periodic reciproing motion sometimes close sometimes leaving in the ...

Crushed stone for the base: what to use

Crushed stone is one of the common fillers for the concrete mix, without which no modern construction of a house or other object can building material has many classifiions and is endowed with different characteristics and features, on which the quality of future construction directly depends, and the strength of concrete, and the strength of the foundation.

Predicted and measured hydraulic conductivity of sand ...

· Crushed limestone with a wide gradation was washed to remove all grains finer than mm (sieve #200) and was sieved through sieves #5, #10, #14, #25, #50, #100, and #200 (ASTM 2017) to yield a group of six gradations, named hereafter "A" grain sizes of these six crushed limestone fractions are limited between and mm, and mm, and mm, and ...

How To Choose The Right Limestone Crusher With High Quality

· When you are working in the mining or construction industry it is very important that you choose the equipment that is going to help you get the most work done. The limestone crusher is a piece of equipment that can help you in many ways and it ensures that you get all of the crushing work done that you need to get done.

Acadiana Shell and Limestone | Limestone | Dirt | Sand ...

Apr 12, 2016 · Since 1984, Acadiana Shell Limestone, Inc. has been taking pride in providing top quality professional work. That is what makes us one of the most well respected limestone and construction companies in South Louisiana. With loions in Abbeville, Lafayette, New Iberia, Krotz Springs, Calumet, Forked Island, and satellite yards in strategic loions throughout South Louisiana, .

working of limestone crusher

Limestone crusher working principle Limestone crusher working principle of limestone crusher is a broken machine which use of impact energy to crushing material When the machine works, under the driving of the motor, the rotor highspeed rotation, the material into the plate hammer function area, and the impact of the rotor plate hammer.

Aggregate Rock Crushing Equipment | Stedman Machine .

Rock Aggregate Crushing Equipment. Limestone, sand, and gravel are used for building and public works projects. These materials are key ingredients in cement and asphalt for construction of roads, buildings, and bridges. Specialty uses of limestone include the manufacturing of pharmaceuticals, toothpaste, paint, paper, caulking, and glass.

All Type of Stone Crusher for Sale | Global Industry Machinery

draw a dodge jaw crusher and its working and construction limestone crushing and mining equipment tub grinder for sale used in germany chromite ore beneficiation processing mills contact person tel 86 penting dari crusher of quality ...

Hammer Mill Crusher Grinder

Feb 25, 2016 · The hammer mill is the best known and by far the most widely used crushing device employing the impact principle of breaking and grinding stone. Thus far we have described machines which do a portion of their work by impact, but the only machine described in which this action plays an important role was the sledging roll type and particularly the Edison roll crusher and in these .

Rockscapes | Kerrville Texas | Natural Stone, Rock ...

The Rockscapes staff has over 85plus years combined experience within the stone, brick and masonry industries. Don't leave it to guess work alone on your next project. Call (830) today or come by Rockscapes LLC and let us assist you with your next stone, masonry or landscape project. Rockscapes carries a wide variety of products to ...

How Much Crushed Stone Do You Need? A SureFire Formula

· Limestone: The most popular crushed stone option, limestone is easily crushed and used in ready mix concrete, railroad ballast, and drain fields. Quartzite: Used for road construction, rubble, and in between railroad tracks due to its durability. Rip rap: Larger stone used for erosion control.

Hammer Mill Crusher Grinder

· The hammer mill is the best known and by far the most widely used crushing device employing the impact principle of breaking and grinding stone. Thus far we have described machines which do a portion of their work by impact, but the only machine described in which this action plays an important role was the sledging roll type and particularly the Edison roll crusher and in these .

Crusher Plant | Mineral Aggregate Processing

Crusher Plant. Crusher plant is a complete aggregate crushing processing, which can be divided into the jaw, impact, cone crushing plant, portable mobile crushing station, quarry crushing plant. Crushing materials that include rock, puzzolana, gravel, limestone, coal, iron ore, construction and demolition wastes, and other mineral raw materials.

Double Roll Crushers | McLanahan

Double Roll Crushers. Double Roll Crushers typically follow a primary or secondary crusher and are used for secondary and tertiary reduction of various minerals, such as ROM coal, clean coal, limestone, gypsum, trona, shale, bauxite, oil shale, coke, salt, lime, glass, kaolin, brick, shale and wet, sticky feeds.

How Does a Concrete Crusher Work

In this blog, we review rock crushing principles, characteristics of bulk materials, types of rock crusher machines we sell, and environmentally successful recycling. Please continue to read to answer the questions of what is a jaw crusher and how does a concrete crusher work.

Crushed Stone in Adams Center, NY | Kings Quarry

The Best Raw Material Available in Adams Center, NY. For over 30 years, Kings Quarry has offered a variety of premium raw materials at competitive prices. Our facility is open six days a week and offers convenient seasonal hours. We have the best availability for stone and topsoil in the area. Our professional team can find everything you need ...

Jaw crusher's advantage of creating limestone for the ...

Jaw crusher is suitable for coarse, medium and fine crushing of various ores and rocks such as limestone, shale, basalt, river pebble and bluestone. It also has simple structure, firmness, reliable work, convenient maintenance and maintenance, production and construction. The cost is relatively low, so it is widely used in mining, metallurgy ...

Experimental Study on Limestone Cohesive Particle Model ...

· This study investigates the effect of impact velocity and particle size on crushing characteristics. We use a discreteelement method simulation and construct cohesive limestone particles with internal microinterfaces and cracks for impact crushing experimentation. The simulation model follows the same process as the impact crushing experiment.

Multiple advantages of jaw crusher for limestone ...

· The crushing ratio is large and the work is reliable. . 2. Saving manpower and improving efficiency: The limestone jaw crusher has a high degree of automation, and basically does not require manual contact with materials, which greatly reduces manpower and material resources investment and reduces production costs.

Latest Posts

- نماذج طاحونة الرطب في رئيس الوزراء والأسعار

- معمل غسيل خام الألمنيوم

- سعر كسارة كينيا في الجزائر

- معدات طحن الإطارات الخردة في مصر

- مروحة تهوية لمطحنة الكرة

- سحق الذهب sbm

- سحق معدات للبيع فلوريدا

- قائمة أسعار كسارة الحجر شنغهاي

- الحجر تكلفة مصنع محطم من أجل الإعداد في ولاية راجاستان

- مصنع استفادة خام الحديد مصر

- مخروط محطم manufactureraustria

- معدات التعدين الهيدروليكية الصين

- 250 300tph متوسطة مصنع الصخور الصلبة للبيع

- كسارة النحاس مطحنة الكرة

- كسارة حجارة فلسطين

- Zenith Crushing Factories In China

- Conveyor Design Calculations And Principles Contents

- Quarry Slag Crusher Plant For Ajmer

- Crusher Tambang Sweeden Dampak

- Small Scale Ore Dressing Mining Equipment

- E Traction Aluminium Help

- jaw crusher ore mm

- Crusher Fujiyama Pe X

- ล้อเจียรกระเบื้อง

- Universal Jaw Crusher Amp Amp Roll Plant Powered

- Gravel Crusher Sand Making Equipment

- concrete crusher rockland

- and tooth spacer for crusher

- Replacing Mill In Cement Factory

- Challenges Of The Market Environment In Mining And Quarry Competition