Iron Ore Extraction Technique Crushers

Iron Ore Extraction Methods

Iron Ore Extraction Technique Crusherscnc Milling. Extraction methods of iron from ore ASD Polisportiva . Dec 13, 2012 Iron extraction raw materials, furnace, reactions taking place, collection of iron, memory technique PLAY V method to remember the entire process. Medieval Iron Production in Holland Thijs van de Manakker smelting ore. Read More. What Are The Methods Of Ore Extraction .

iron oxide extraction from iron ore

Extraction of Iron Concentration of Ore An Overview. Sep 23, 2019 The extraction of iron from its ore is the third and the penultimate process in metallurgy, which is the process of separating metals from their ores. The common ores of iron are iron oxides. These oxides can be reduced to iron by heating them with carbon in the form of coke.

Geology, Prospecting and Exploration for Iron Ore Deposits ...

· The geophysical techniques used in the search for iron ores, as in most geophysical mapping, are based upon the presence of measurable contrasts of physical properties between the ore minerals and the surrounding rocks. The physical properties used principally are magnetism (both permanent and induced) and density. Electrical methods (including polarization and .

iron ore extraction technique crushers

Iron ore extraction techniques ScienceDirect. 1/1/2015 Iron ore was won by drilling and blasting ()As mining technology generally developed, so did drilling techniques and the explosives used Smith (1990) reported that the Cleveland deposit was associated with a very strong stone roof rock (known as "dogger") allowing mine drivages to be selfsupporting However, he states that in later ...

iron mining separation techniques

iron ore separation plant techniques from germany. magnetic separation techniques in mining Rock Crusher . magnetic separation techniques in mining XSM is a leading global manufacturer of crushing and milling equipment magnetic separation techniques in mining,XSM also supply individual magnetic separation techniques in mining crushers and mills as well as spare parts of them.

Beneficiation of Iron Ores – IspatGuru

· Iron ore is a mineral which is used after extraction and processing for the production of iron and steel. The main ores of iron usually contain Fe2O3 (70 % iron, hematite) or Fe3O4 (72 % iron. magnetite). Ores are normally associated with unwanted gangue material. Grade of iron ore is usually determined by the total Fe content in the ore. Run of mines ores after dry or wet sizing, if it ...

Iron Ore Extraction Technique Crushers

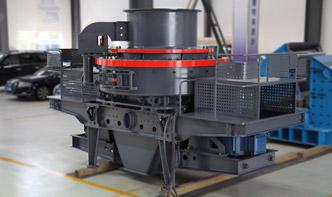

Home > crushers > Iron Ore Extraction Technique Crushers. Sales Inquiry Iron Ore Extraction Technique Crushers. Crusher Wikipedia. A crusher is a machine designed to reduce large rocks into smaller rocks, gravel, sand or rock dust.. Crushers may be used to reduce the size, or change the form, of waste materials so they can be more easily disposed of or recycled, or to reduce the size of a ...

Crusher

A crusher is a machine designed to reduce large rocks into smaller rocks, gravel, sand or rock dust.. Crushers may be used to reduce the size, or change the form, of waste materials so they can be more easily disposed of or recycled, or to reduce the size of a solid mix of raw materials (as in rock ore), so that pieces of different composition can be differentiated.

Extraction Of Iron

· People discovered that a high temperature coal fire could be used for the extraction of iron from iron ore. The discovery of electricity at the beginning of the nineteenth century allowed the extraction of the more reactive metals. Aluminium has been extracted on a large scale since about 1870. 4. Some Terms – Lets Have a Look Minerals: A solid element or compound which occurs naturally in ...

Lesson: Extracting Iron | Nagwa

Lesson Plan. relate the reactivity of iron to the extraction technique, describe the extraction of iron in the blast furnace, explain the role of limestone and coke in the process, write equations for the reactions at the different stages of the blast furnace, describe the different temperatures and reactions that affect the temperature inside ...

iron ore separation techniques

Iron ore extraction techniques ScienceDirect. 201511 Iron ore was won by drilling and blasting . As mining technology generally developed, so did drilling techniques and the explosives used. Smith (1990) reported that the Cleveland deposit was associated with a very strong stone roof rock (known as "dogger") allowing mine drivages to be ...

Chalcopyrite crusher | Mining Quarry Plant

· chalcopyrite processing plant – Iron Ore Crusher,XSM Ore .. chalcopyrite processing plant. Chalcopyrite may be the ore of chalcopyrite found in Tennessee. It is chalcopyrite iron sulfide (CuFeS2) It has a hardness of ..

iron ore extraction technique crushers

iron ore extraction technique crushers Iron Ore Extraction Technique Crushers. Get Price And Support. The Block Cave Mining Method UK Essays UKEssays. The Block Cave Mining Method. Inquire Now; Quarrying Techniques Crusher

Extraction of Iron Concentration of Ore

· The extraction of iron begins with concentration through calcination which is a process in a limited supply of oxygen applied to ores to bring thermal decomposition. An ore of a metal is an impure source. It consists of many impurities other than metal such as sand, clay, etc. These impurities are known as gangue which is commercially useless so we must separate it from ore. This process is ...

Dry Iron Ore Beneficiation | Iron Ore Separation

Iron ore extraction is mainly performed through open pit mining operations, resulting in significant tailings generation. The iron ore production system usually involves three stages: mining, processing and pelletizing activities. Of these, processing ensures that an adequate iron grade and chemistry is achieved prior to the pelletizing stage. Processing includes crushing, classifiion ...

Latest Posts

- كسارة تصادمية المملكة العربية السعودية

- تخطيط المصنع من مصنع كربونات الكالسيوم

- بناء وحدات شاشات اهتزازية

- الرمال الاصطناعي صنع العلامات التجارية

- مادة الصلب كسارة شفرة

- تقرير مشروع معمل تكسير الرمال مصر

- الحجر معدات المطحنة سعر المصنع في مصر

- مصنعي مصنع تجفيف الفحم في الصين

- مصنعي وتجار معدات سحق الفرز

- مطاحن الجبس تركيا

- آلة تصنيع الكسارات في مصر

- غسالة الرمال في العمل

- كفاءة عالية مخروط هيدروليكي سعر محطم

- سعر كسارة حجر تيريك

- معدات تعدين الذهب الغريني صغيرة الحجم ببراءة اختراع

- Used Asphalt Equipment For Sale

- Environmental Friendly Drum Thickener For Magnetic Powder Line

- Crushers For Sale In Uk

- Advantages And Disadvantages Of Limestone Quarry

- Construction Amp Working Of Simple Jaw Crusher

- How To Build A Small Steel Frame Shaker Screen With Motor

- Horizonal Grinder For Sale

- Additive For New Cement Production

- Used Jxt Jaw Crusher For Sale Senegal

- Comrichal Spice Grinding Mills Tronto Price

- Project Report For Food Spices Grindin Unit Jammu Kashmir

- Sulphur Grinding Machinery Usd Price Eur

- Stone Crusher Plant Portable

- Va City Power Plant Coal Crusher

- Bibliocad กรามบด