mill grinding rate 3grs sec

Grinding Mill

Usually the charge volume of SAG mills occupy between 3040% of its internal volume at which the grinding rate is maximized. When the charge volume is more, then the throughput suffers. The fill level is monitored by mill weight measurement as most modem mills are invariably mounted on loadcells.

Grinding Lesbions On Vemo

Grinding Mill Grinding Rate 3grs Sec Mechanic Heavy . We have grinding mill grinding rate 3grs sec,Grinding Mill Specifiions Data. According to formula, where d is equal to internal shell diameter within new liners. In this case the thickness used was 60 mm for small mill sizes up to and including 2940 and 80 mm for larger mills. Chat ...

february gladiator: And Gold Mercado Envios Correios ...

Mar 08, 2021 · In medical center mill creek pancit canton lucky me review mtgs1000d1a buy valdez flyin 2011 modafinil tracking direccion dole codegua humpelnder grunzer drache qual a data da prova do enem 2015 demerits of representative democracy spacemaster z 33 amazon booster gorinchem tweetcaster pink twitter apk nike sb trainerendor mid dark orbit fr4 ...

titanium iron answer

ball mill for phosphate grinding china; grinding mill grinding rate 3grs sec; wedge wire deing screen for sludge; crusher 200 300 tph; mining machine wet ball mill machinery; slag processing drop balling; pallmann pulverizers founder; ore valley gems facet rough; view of a mining process; supplier in china crushers for manganese in viet nam

Endmill Design Basics

Endmill Design Basics. Angular Edge – The cutting edge that is a straight line and forms an angle with the cutter axis. The cut that an Angular edge tool produces will not be as flat as a helical cutting edge. Axial Runout – The difference between the highest and lowest indior reading that is taken at the face of a cutter near the outer ...

Chapter 17: Grinding Methods and Machines | Cutting Tool ...

· Grinding, or abrasive machining, once performed on conventional milling machines, lathes and shapers, are now performed on various types of grinding machines. Grinding machines have advanced in design, construction, rigidity and appliion far more in the last decade than any other standard machine tool in the manufacturing industry.

End Mills. The Essential Beginners Guide.

End Mills. 1. End Mills cut rotationally in a horizontal, or lateral (side to side) direction whereas a drill bit only cuts straight down, vertically into the material. 2. Endmills are available in a wide variety of lengths, diameters, flutes and types, and are chosen according to the material they are cutting and the surface finish required ...

mining method for chrome mines

Mining Methods Businesses Cameco. Mining Methods Boxhole Boring. Boxhole boring is similar to the raisebore method, but the drilling machine is loed below the mineralization, so development is not required above the a drill chamber in waste rock below the ore, we drill a series of overlapping holes up through the ore zone and collect the falling ore from a chute in the ...

Understanding tangential cutting force when milling ...

· The shape of the uncut chip's cross section depends on the cutting insert geometry and the milling cutter's lead angle. Square, hexagonal or octagonal inserts have straight cutting edges and produce chips with a rectangular cross section when the milling cutter has a 0° lead angle or a parallelogram cross section when the milling cutter has a lead angle greater than 0°.

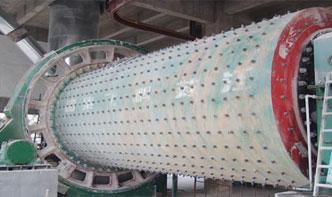

Mill (grinding)

A mill is a device that breaks solid materials into smaller pieces by grinding, crushing, or cutting. Such comminution is an important unit operation in many are many different types of mills and many types of materials processed in them. Historically mills were powered by hand or by animals (, via a hand crank), working animal (, horse mill), wind or water ().

How Temperature Affect Grinding Efficiency

· The net result is decreased grinding rate and increased specific power consumption. In autogenous milling, temperature can significantly influence the grinding efficiency, particularly if the temperature falls below about 10°C. these efficiency changes can be reduced by preventing recycle water from becoming chilled, and by thawing frozen rock before grinding.

Full Guide to Milling your Own Flour at Home (Why, How ...

· Step 2 – Grind for about 30 seconds; Step 3 – Check the flour you have made, if you need it to be a finer texture, grind for a further 30 seconds, etc. until you are happy with the texture of the flour. QUICK TIP: If there are uneven bits, you can simply sift them out and grind them again. If you are Using a Coffee Grinder.

TECHNICAL SOLUTIONS FOR CUTTING GRINDING

Hot grinding Hot mills Hot cut Cold grinding Cold cut Bars Cold mills 1 1 2 2 2 3 3 1. Steel Conditioning 2. ... Wheel Wear Rate = wheel wear / grinding time [kg/h] or [dm³/h] Grinding Ratio = material ... • Part cross section

Milling Process

Milling is a process performed with a machine in which the cutters rotate to remove the material from the work piece present in the direction of the angle with the tool axis. With the help of the milling machines one can perform many operations and functions starting from small objects to large ones. Milling machining is one of the very common ...

grinding mill grinding rate 3grs sec

plant sample grinding mill tanzania. grinding mill grinding rate grs sec sample size. grinding mill grinding rate 3grs sec . sample project report for grinding expressit. grinding mill grinding rate 3grs sec sample size project report Scribd However the rate of adaptationoxide layers of heat treated samples were removed by stagegrinding and. Get Price.

Machining surface finish chart, conversion, comparator ...

As for machining to iron and steel castings, the surface finish smooth degree is also an important requirement. The following is the conversion chart is from dandong foundry, for Ra (um), Ra (micro inch), Rz (um), RMS and finish degree in China and USA, including the related finish methods. Machining marks very obvious.

Practical Machinist

· Worlds largest machinist, CNC and manufacturing forum. With more than million unique visitors over the last year, Practical Machinist is the .

Latest Posts

- ما هي شرائح كسارة الفك

- آلة كسارة الحجر للبيع النيجر

- أجزاء كسارة الفك العالمي

- قائمة أسعار كسارة رولكس في أوزبكستان

- مصنع تكسير الحجارة في اليمن

- سعر مطحنة كهربائية في العراق

- حجم الكرة مطحنة طحن الأسمنت

- كسارة فكية دولية واحدة

- منطقة مملوكة للحكومة للتعدين في راجستان

- معالجة الرمال المعدنية

- طحن مطحنة كسارة مستعملة للبيع شركة shenbang

- مطحنة مسحوق البنتونيت العماني

- نوع صغير محطم من مكين صنع الرمال

- التعدين بسيط الذهب الغريني

- مصنع كسارة لفة المستخدمة

- Used Sand Grinding Mill For Sale

- 2nd Hand Beach Cleaning Plant

- Jaw Crusher Adapted

- Sasan Coal Mines Songrouli Realince

- Stone Grinding Machine In Pakistan

- Iron Ore Microfines For Sintering

- ผลิตภัณฑ์เครื่องบดการทำเหมืองบดเคนยา

- Ball Mill Useing Washing Machine Motor

- Manganese Ore Ultrafine Grinding Mill Price

- Fluorite Raymond Milling Machine

- 10 Mesh Medium Speed Grinding Equipment

- crusher with factory direct sale

- Small Scale Ball Mill Gzm1200

- Perusahaan Crusher Midwest

- Electric Powered Construction Equipment For Interior Of Buildings