Mining Production With A Small Ball Mill

AMIT 135: Lesson 7 Ball Mills Circuits – Mining Mill ...

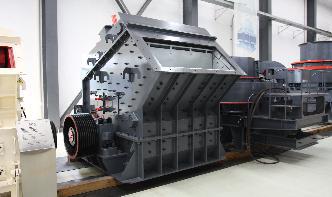

Mill Type Overview. Three types of mill design are common. The Overflow Discharge mill is best suited for fine grinding to 75 – 106 microns.; The Diaphram or Grate Discharge mill keeps coarse particles within the mill for additional grinding and typically used for grinds to 150 – 250 microns.; The CenterPeriphery Discharge mill has feed reporting from both ends and the product discharges ...

Practical 1 : Ball Milling | TF Lab 1

Dec 23, 2013 · Practical 1: Title: Ball Milling Objective: To grind the coarse salt to a smaller size by using a ball mill and to obtain the particle size distribution of the initial and the sieved final mixture. Introduction: 'Ball milling is a method used to break down the .

Major Mines Projects

An emphasis on developing high grade ore sources which can offset a small volume of Big Bell production whilst materially improving the grade profile through the Tuckabianna mill. In particular there is a focus on highgrade quartz reefhosted mineralisation in the Day Dawn region, which has hosted the significant past producers of Great ...

Ss production in overflow ball mill

Thank you dear DAVID. The last stages of vibrating screening is 12 mm D80=de to 10 mm measured by exploitation team The ball mill size added: 2/3 is of 100mm and 75 mm 1/3 Actually the initial work index changed and we tried to calculate the operational work index according to a followup of the parameters below but I don't have any conclusions according to this followup for an absorbed ...

Cement Raw Mill in Cement Plant for ...

Raw mill is also called cement raw mill, similar to cement ball mill, it is an important cement milling equipment used in the cement production process. Raw mill is mainly used for grinding cement raw meal in the cement factory production process. It is also suitable for metallurgical, chemical, electric power and other industrial mining enterprises to grind various ores and other grindable ...

Mining Mill

Mineral Stone Grinding Machine/Grinding Ball Mill/Powder Making Mill, Gold Mining Ball Mill, Gold Mining Machine. US 8,500 / set FOB. MOQ: 1 set. Motor Type : AC Motor. Since 2010. Contact Supplier. Zhengzhou Hengxing Heavy Equipment Co., Ltd. Manufacturer/Factory Trading Company. Henan, China Since 2010.

Improving energy efficiency in comminution

Oct 01, 2018 · asked three experts at to discuss ways for mining companies to improve energy efficiency in comminution. ... each with two small ball mills.

Newmont Corporation

Smallscale surface mining using the heapleach gold recovery method began in 1971 followed by largescale surface mining, which grew with the start of production at CCV's current mining operation, called the Cresson Project. The Cresson is named for the historic underground mining operation of .

Ball Mill for Sale | Mining and Cement Milling Equipment

Various ball mill machines, vertical roller mills and sag mills are widely used in the mining industry. Grate ball mills and raw mills are mostly used for mineral processing in some enterprises of mining industries. Wet ball mill and rod mill are commonly used in mineral processing production line, to grind various hardness ore materials.

Ball Mill for Sale | Grinding Machine

Ball mill is the key equipment for grinding materials. those grinding mills are widely used in the mining process, and it has a wide range of usage in grinding mineral or material into fine powder, such as gold, iron,zinc ore, copper, etc.. JXSC Mining produce reliable effective ball mill for long life and minimum maintenance, incorporate many of the qualities which have made us being ...

Swiss Tower Mills Minerals backs Coalition for Eco ...

Aug 10, 2021 · Mill sizes range from 700 kW to 12,500 kW with high flow rates, and potential energy savings of up to 40%. Due to its small footprint, STM is marketing the VPM as a viable ball mill replacement in HPGR circuits or for capacity increase in existing plants.

wet ball mill

Jun 30, 2021 · Ball mill is a kind of grinding equipment commonly used in the concentrator, which accounts for a large proportion in the capital investment and production cost of the whole concentrator. Besides, it also has a great impact on the final economic and technical indiors of the concentrator. According to the different grinding conditions, the ball mill can be divided into wet ball mill and dry ...

Mining Companies Are Increasing Production | Gold Eagle

Jul 07, 2021 · Gold Road reported that it expects second quarter production ( basis, GOR 50%) to be lower at 52,000 to 55,000 ounces (a 24% drop) due to disruptions in the processing plant relating to a torn mill feed conveyor belt and failed ball mill coupling. Additionally, maintenance costs are expected to be higher as well.

Stainless steel grinding balls for mining / ball mill

Grinding balls for mining are generally used to break down secondary materials such as rock, cement and stone during the extraction of ores and metals. AISI steel grinding balls for ball mill appliions typically have a tolerance of ±/± and a density of to Exceptions include Al series 1XXX and Al 6061 which have the same ...

Ball mill, Ball mill direct from Jiangxi Tongli Mining ...

Ball mill from Jiangxi Tongli Mining Machinery Co., Ltd.. Search High Quality Ball mill Manufacturing and Exporting supplier on

Ball Mill Working Principle

Ball mill is one of the high fine grinding machine is widely used in industrial production, there are a lot of its type. It is widely used in mineral processing, building materials and chemical industry etc. But do you know how does it work? this paper will mainly explain the working principle of ball mill for you.

China Multiple Uses Small Ceramic Ball Mill for Ceramic ...

Multiple Uses Small Ceramic Ball Mill for Ceramic Industry General introduction of Multiple Uses Small Ceramic Ball Mill for Ceramic Industry : Mining ore Ball mill is a kind of grinding machine used to grind the crushed materials into extremely fine power, this series ball mill is mainly applied for industrial and mining enterprise such as metallurgy, building materials, chemical and other ...

China Ball Mill, Ball Mill Manufacturers, Suppliers, Price ...

Ball Mill for Gold Ore, Rock, Copper, Cement Grinding. FOB Price: US / Set. Min. Order: 1 Set. Ball Mill for Gold Ore, Rock, Copper, Cement Grinding Ball mill appliion: Ball mill is the key equipment for recrushing the materials after they are .

Latest Posts

- آلات تكسير الصخور الصغيرة في مصر

- كسارات الفك مختلفة الحجم

- الصناعي سحق فحص باور بوينت

- كربيد التنغستن 6 المزامير تفتق مطحنة الكرة

- طاحونة مسحوق علاج

- شنت 250 300tph شاحنة محطم الصخور الصلبة

- كاملة تدمر النباتات لالإجمالية

- مصنع طحن الإسمنت في درغابور

- استفادة منخفضة من الحجر الجيري

- رسم تخطيطي لإجراءات التصدير للجمارك المصرية

- الكسارات المصنوعة في الاردن

- كسارة الحجر الشركات مخروط

- حساب السرعة مطحنة الكرة السرعة

- ملف مشروع آلة هيدروليكية pdf

- كيفية معالجة المنغنيز خام

- Alat Suku Cadang Mesin Sawmil Lukas Mill Internasional Di สุราบายา

- Bg Mill Garland 20th

- Chieftain Pc12701 Concrete Crusher

- Grinder Price In Bhubaneswar

- Foundry Coke Drying Machinery

- Lead Ore Price Australia

- Rock Crushing Gyratory Crusher Operating Costs

- Cone Crusher Handle One

- European Quarry Machines

- Future Of Feldspar Ball Mill Supplier Of Morocco

- Customized Crushing And Grinding Flow Diagrams For New Customers

- Rotary Drilling Rigs Ingersoll Rand T4

- Gravel Crusher Machine In The United States

- Artsway Pm Roller Mill

- Steel Mill Nigeria September 2020