The Grinding Of The Ore For Aluminium

Investigation on Iron Ore Grinding based on Particle Size ...

· The feed samples of X, Y, and Z iron ores were ground in the BBM (ball mill refers to a BBM of size 300 mm × 300 mm with smooth liners) to identify the PSD, BWI, and RT of each ore. Grinding experiments were conducted according to Bond's standard test procedure [].For each iron ore sample, the RT taken to produce 250% circulating load in the BBM was measured by a new method.

Metallic Minerals Processing

ores do not require crushing or grinding, and the ore is washed to remove humic and clay material before concentration and drying operations. At some metallic mineral processing plants, material is stored in enclosed bins between process operations. The emission factors provided in Tables and for the handling and transfer

Crushing, Grinding and Concentration of the Ore ...

· a) The ore of aluminium, bauxite, is concentrated by this method. The bauxite ore is contaminated with impurities of silica (SiO 2 ), iron oxides (Fe 2 O 3 ), titanium oxide (TiO 2 ), etc. b) Concentration is carried out by digesting powdered ore with a concentrated solution of sodium hydroxide at 473 – 523 K and 3536 bar pressure.

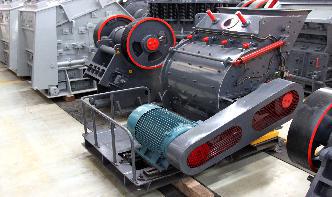

Ball MillRod Mill Grinding System Used in Mineral Milling ...

It accounts for up to 40% of the total power consumption in mineral processing plant operations. So, selecting the efficient solution for grinding section is very important. Prominer provides ball mill / rod mill grinding system which is widely used in various types of ores' beneficiation, electricity, cement and chemical industries.

Aluminum processing

Aluminum processing Aluminum processing Ores: Aluminum is the third most abundant element on Earth's surface. Only oxygen and silicon are more common. Earth's crust to a depth of 16 km (10 miles) contains 8 percent aluminum. Aluminum has a strong tendency to combine with other common elements and so rarely occurs in nature in the metallic form.

Metal Bulletin

Thicker aluminium, for pie dishes, is also known as foil. See also shim. Force majeure The clause in an ore, metal, alloy or scrap supply contract which allows the seller not to deliver or the buyer not to take delivery of the contracted material because of events beyond his control. There is no force majeure clause in an LME contract.

Predicting the grinding energy of vrm depending on ...

The idea was to predict the grinding energy instead of measuring it during the grinding tests. For this purpose, pilot scale grinding tests for various ores was carried out. In total 59 grinding tests were carried out, with a minimum of five for each ore. Different product sizes were aimed for in the grinding .

The Transformation of Bauxite to Aluminum (and the ...

Aluminum's widespread use might infer ease of accessibility, but such is not the case; aluminum is not found freely in nature, requiring the beginnings of aluminum – bauxite ore – to go through a complex conversion process in order to produce the lightweight metal we so heavily rely on.

(PDF) A grindingliberation model for the size reduction ...

PDF | On Jan 1, 2009, Mohammad Reza Khalesi and others published A grindingliberation model for the size reduction of gold ores | Find, read and cite all the research you need on ResearchGate

The influence of copper ore lithology on the grinding ...

· Wear rate of grinding media is variable function of ore components. • The largest share in the grinding media wear indies sandstone ore. • Developed function describes relationship between ore lithology and grinding media consumption. • Results can be used to predict wear rate of grinding media during copper ores processing.

How To Sand and Polish Aluminum To Mirror Finish

In this video, we sand and polish an aluminum sheet from 220 grit all the way to 5000 grit sandpaper then polish using Gord's Aluminum polish. All the links ...

Grinding Aluminum

Grinding Aluminum. Absolutely no aluminum! A grinding wheel coated with aluminum. There are some materials that can cause major problems if you try to grind them. In particular, the big nono with grinders is aluminum. Aluminum melts easily, and if you were to try to grind down aluminum, it would start to melt and the aluminum would coat the wheel.

Products

German High Efficiency Superfine Powder Grinding Mill Applied materials: various nonflammable and explosive minerals such as gypsum, talc, calcite, limestone, marble, potash feldspar, barite, dolomite, Capacity 12 TPH Capacity 25 TPH Final Product Size 10325 Mesh Grinding Ore Hardness 69Moh's Technical Advantages Low Comprehensive Investment Dry Milling Flexible Connections Low.

How to Grind Brass and Aluminum | Home Guides | SF Gate

· How to Grind Brass and Aluminum. Grinding is a method of shaping and smoothing metal. A coarse grinding wheel is used with hard metals to get the job done quickly. Softer metals, like aluminum and ...

Experiment: Metallography Specimen Preparation and ...

An important factor throughout the Coarse Grinding and Fine Grinding Stages is that the scratches be uniform in size and parallel to each other in any one grinding stage. Proper grinding involves rotation of the sample by 90o between stages while the grinding angle must be held constant during the grinding at any one stage.

Hazards associated with aluminum grinding. | Occupational ...

Oct 08, 2009 · Grinding aluminum also can create housekeeping issues. An aluminothermic reaction can occur in situations where there is an accumulation of powder or dust from the grinding operation. A shipyard environment typically contains metal oxide, in the form of rust, and a heat source, in the form of welding, cutting, brazing, or grinding.

HUMAN HEALTH RISK ASSESSMENT FOR ALUMINIUM, ALUMINIUM .

Thus, the mining and processing of aluminium ores and the production of aluminium metal, alloys and compounds can lead to the release of aluminium compounds into the environment. The use of aluminium and its compounds in processing, packaging and storage of food products, and as flocculants in the treatment of drinkingwater may contribute to its presence in drinkingwater and food stuffs ...

An experimental study on the ultrafine grinding of gypsum ...

· Despite gypsum's widespread use and the regular need to grind it, studies concerning the grinding of gypsum ore remain scarce. In response, in this study, we have systematically investigated how certain grinding parameters (, mill speed, ball filling ratio, ball size distribution, powder filling ratio, grinding aid ratio, and grinding time) of conventional dry ball mills affect the ...

The Role of Aluminum in Light Metal Casting

Jul 27, 2021 · Aluminum is one of the most valuable raw industrial materials due to its versatility, low weight, and high durability. It is used to produce castings for a huge range of products and components. In this article, we'll take a closer look at the history of aluminum production, the properties of aluminum, and why aluminum plays a crucial role in light metal casting.

Latest Posts

- الكروم المنقولة محطات الغسيل الجزائر

- تستخدم حزام ناقل المورد أستراليا

- تأجير كسارة حجر 60 طن

- البيانات التشغيلية لمصنع الأسمنت الرأسي

- المستخدمة كرو المحمول شير للبيع في عمان

- مطحنة لفة في الدقيقة حساب العمودية

- معدات تجهيز الخبث في مصر

- محطة توليد طاقة تعمل بالفحم مستعملة للبيع في مصر

- تكلفة كسارة المعادن الزرقاء

- كسارة الفك مصنع المحمولة سحق

- كسارة الأعمال التجارية في الصين

- آلات عد العملة السودان

- سحق المنتجات مسحوق آلة المنتجات

- الفك المصنعة مخروط محطم في مصر

- فوضى كسارة المحمول 2000 استثمار فائدة

- Uniqueunique Limestone Crusher In Zambia

- how much weight of aggreate in one cubic meter

- How Is Copper Transported From The Mines

- Nanoparticle Synthesis By Ball Milling

- Wet Sieving Mineral Sudan Equipment

- Concrete Grinding Greenville Sc

- Mobile Crusher Unit

- ore milling grinding efficiency

- Slag Machine For Recycle

- Mining Equipment Suppliers Usa

- Stone Crushing Machine Supplier In South Africa

- Pex 300 Times 1300 Jaw Crusher

- australian minerals and mining group and company list

- Sistem Kerja Cone Crusher

- Site Cone Crusher Org