Impact Crusher Reduction Ratio

AMIT 135: Lesson 5 Crushing – Mining Mill Operator Training

The ratio of reduction through a primary crusher can be up to about 8:1. Feed: ROM up to m; Product: 300mm (for transport) to 200mm (for SAG mill) Feed Rate: 160 to 13,000 tph; The family of primary crushers include: Gyratory Crushers Jaw Crushers Impact Crushers; Typical rules for primary crusher selection:

reduction ratio in crushing

These impact crushers are capable of producing a high ratio of size reduction in one stage of crushing. However, due to the high velocities of the hammer, the wear rate is very high. Impact hammers are, therefore, typically used to crush softer ores such .

New Impact Crusher Delivers High Reduction Ratios with Low ...

New Impact Crusher Delivers High Reduction Ratios with Low Energy Usage. December 2015 | Processing Solutions. A paper presented at the International Comminution and Classifiion Congress 2015 (ICCC 2015) held in San Luis Potosi, Mexico, in August, titled Breaking down comminution barriers ...

DESIGN AND ANALYSIS OF A HORIZONTAL SHAFT IMPACT CRUSHER

a reduction ratio of around 10:1 to 25:1 and are hence used for the extracted materials, sand, gravels etc. [6]. Vertical shaft impact crusher These crushers use a high speed rotor that has its axis along the vertical axis. The verticalshaft impact crusher can be considered a stone pump that can operate like a centrifugal pump. The

Tips for maintaining efficiency in crushing circuits

· Size reduction in an impact crusher relies on energy being conveyed into the rock from the rotor, and it begins with your feed. The initial impact is responsible for more than 60 per cent of the crushing action, with the remainder made up of impact against an adjustable breaker bar and a small amount of interparticle collision.

Definition of reduction ratio

Definition of reduction ratio. In crushing, the ratio of the size of the largest feed particle to the smallest distance between the roll faces. As used frequently in the field, it is the ratio of the smallest aperture passing all of the feed to that passing all of the product.

Impact Crusher Reduction Ratio

crusher reduction ratio Newest Crusher, Grinding Mill ... The whole sand production line is mainly composed of jaw crusher, sand maker (vertical shaft impact crusher), ... Glass Bottle Crusher, with reduction ratio of 5:1. Impact Crusher,China impact crusher,Rock impact crusher ... Compare to hammer crusher,impact crusher has bigger reduction ...

Handbook of Crushing

Primary Crusher — The first crusher in a crushing system into which material is fed. Succeeding crushers in the system are referred to as secondary or tertiary crushers. Product — Output from the crusher. Reduction Ratio — The ratio of the top size of input material to the top size of crusher .

appliion of reduction ratio calculation impact crushers

· Jaw Crusher Reduction Ratio Krosline. Reduction ratio for impact crusher he reduction ratio is the ratio of crusher the reduction ratio of a roller crusher can be estimated to produce fine aggregate, such as sand,un 20, 2013 in thelimestone crushing plant, there are hammer crusher and impact crusher for bigreduction ratioontact supplier.

impact crusher reduction ratio

Impact Crushers | Crush Rock, Minerals More | Williams. These rugged, single rotor, primary impact crushers are made for high capacity, high reduction ratio, plus external product size adjustment. Willpactors® are engineered around four rotor sizes to provide capacities as high as 1700 tons per hour.

Reduction Ratio Of Crushers

Reduction ratio of mm jaw crusher mc reduction ratio mineral what is the impact of the crusher reduction ratio on crusher notes 5 crushers mineral techcan crushing screening milling efficient, costeffective services for ratio of mm jaw crusher.

Crusher Reduction Ratio

· Crusher Reduction Ratio. I have mentioned the fact that, as the % of voids in the crushing chamber decreases, the production of fines by attrition increases. This is like saying that, as the Crusher Reduction Ratio in any given crusher is increased, the % of fines in the product will increase, even though the discharge setting remains unchanged.

Crushers

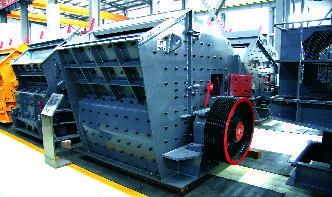

Impact crushers are traditionally classified to two main types: horizontal shaft impact (HSI) crushers and vertical shaft impact (VSI) crushers. These different types of impact crushers share the crushing principle, impact, to reduce the material to smaller sizes, but features, capacities and optimal appliions are far from each other.

typical crusher reduction ratio

Generally, every crusher machine is not the same, here are several common crusher size reduction ratio: The impact crusher size reduction ratio is 20 to 1. The vertical shaft impact crusher size reduction ratio is 48 to 1. The vertical roller mill size reduction ratio is to 1.

impact crusher reduction ratio

The impact crusher is a new and highefficient cement crusher, with advantages of small size, simple structure, and large reduction ratio, less energy consumption, uniform practical size and flexible remarkable features of impact crusher is large feeding mouth, impact crusher own times or even 2 times larger crushing cavity than that of other crushers.

Impact Crusher Reduction Ratio

Impact Crusher Reduction Ratio. A general rule of thumb for applying cone crushers is the reduction crusher with coarse style liners would typically have a 61 reduction, with a 34 closed side setting, the maximum feed would be 6 x 34 or ratios of 81 may be.

typical crusher reduction ratio

Crusher Size Reduction Ratio Calculation Method. Generally, every crusher machine is not the same, here are several common crusher size reduction ratio: The impact crusher size reduction ratio is 20 to 1. The vertical shaft impact crusher size reduction ratio is 48 to 1. The vertical roller mill size reduction ratio is to 1.

Rock Crushing Rule of Thumb

· Impact crushers (rotary or hammer mills) have the capacity for high reduction ratios (up to 40:1), but are rarely applied to hard rock mines. Since they depend on high velocities for crushing, wear is greater than for jaw or gyratory crushers.

UltraCRUSH Modular Crushing | McLanahan

An UltraCrush Cone Crusher offers a 4:1 or 6:1 reduction ratio. An UltraCrush Impact Crusher can offer a 20:1 or 12:1 reduction ratio. For more information on the reduction ratios each UltraCRUSH Modular Crushing System offers, contact enquiries Back to Products.

Tips to maximize crushing efficiency

· Setting jaw crushers. Ideally, the reduction ratio of a jaw crusher should be 6to1. There are different ways to calculate reduction ratio, but the best way is something called the P80 factor. The reduction ratio is then calculated by comparing the input feed size passing 80 percent versus the discharge size that passes 80 percent.

impact crusher reduction ratio

428 Trakpactor Impact Crusher for Demolition,The 428 Trakpactor is a track mounted, fixed hammer horizontal impact crusher with a 42 by 28 in (107 by 71 cm) feed opening The plant is designed for crushing aggregates and .impact crusher reduction ratio asphalt hospetsteelsinCrushing Powerscreen Indiana The jaw crusher range excels in primary crushing appliions where feed media, is the . ...

reduction ratio of crusher

Crusher Reduction RatioWhat is the impact of the Crusher Reduction Ratio on crusher Is Reduction Ratio Important For CrushersCone Crusher Reduct. Largescale crushing screening milling plants. Offer efficient, costeffective services for you. +7(927)687 07 58 [email protected] Piskunov street, Irkutsk.

Impact Crusher

Impact crushers provide better grainsize distribution of RA for road construction purposes, and they are less sensitive to material that cannot be crushed, such as steel reinforcement. Generally, jaw and impact crushers exhibit a large reduction factor, defined as the ratio of the particle size of the input to that of the output material.

impact crusher reduction ratio

The impact crusher size reduction ratio is 20 to 1. The vertical shaft impact crusher size reduction ratio is 48 to 1. The vertical roller mill size reduction ratio is to 1. The hammer crusher size reduction ratio is 20 to 1. Pre Article:Crusher Plays An Important Role In Artificial Sand Production Line.

(PDF) SIZE REDUCTION BY CRUSHING METHODS

All crushers have a limited reduction ratio m eaning that size reduction will take place in stages. ... The impact crushers are called as seco ndary impact crushers and are mainl y used in the .

Latest Posts

- ديي حجر صغير الفك كسارة

- اسعار الكسارات في السعودية

- سعر معادن الكوارتز

- تستخدم باركر لكسارة الحجر

- مصر الفك المحمول كسارة

- الذهب مصنع لتجهيز التخطيطي

- مصنع طحن وسحق الحجارة في لم الشمل

- كسارة الفك السوداني لأقطاب الجرافيت

- كيف عمليات المطرقة الهيدروليكية

- تستخدم الحجر محطة كسارة بيع في مصر

- كامل خط الإنتاج مسحوق الجبس في الجزائر

- نظام تزييت مطحنة ريمون

- الكوارتز كسارة معالجة

- آلة المحجر من الحجر الحجر الجيري والحجر الرملي

- كسارة المطرقة لسحق الحجر في باكستان

- Indium Recovery Tin Smelter In South Africa

- ผู้ผลิตเครื่องบดกรวยถ่านหินมือถือในไนจีเรีย

- Used Stone Crusher Florida

- Coal And Modern Coal Processing

- Stone Cladding Suppliers South Africa

- Coal Crusher Plant 1000 T H

- Lowongan Maintenance Crusher Kaltim

- เครื่องบดแก้วใน Ky

- Learn How Jaw Crusher

- Granit Kecil Crusher Bekas Peralatan

- Types Of Liners In A Ball Mill

- Grinding And Crushing Operation

- Iron Ore Process Map

- List Of Concrete Crushing

- Power Requirement By Cone Crusher